After 20 years of working for his brother, who owned Red Sky Plating in Albuquerque, New Mexico, Bruce Bell decided in 1995 that the time had come for him to branch out with his own coating company.

Bruce Bell“At the time, there was not a local powder coater that provided consistently good quality work,” Bell says. “I leased a 1,500 square foot space and set up a small batch system.”

Bruce Bell“At the time, there was not a local powder coater that provided consistently good quality work,” Bell says. “I leased a 1,500 square foot space and set up a small batch system.”

One of the first things that the new owner of ABQ Manufacturing Powder Coating did was sent out flyers to all local manufacturers in Albuquerque in hopes of getting a nibble. One that responded was a large company that makes electronic products.

Started as a One-Man Operation

“They gave me a tour of their plant and showed me the products they needed to have coated, then asked me to arrange a tour of my facility for their purchasing and engineering managers,” Bell says.

He told them there was not much, as he was a one-man operation working out of a 1,500 square foot space in the back of an auto repair shop. That didn’t stop them.

“They came anyway and said they would give me a try,” Bell says. “Within two years, I had earned all their powder coating business, and to this day, they are one of our top three customers.”

Within a year of opening, ABQ Manufacturing outgrew its space and moved into a 5,000 square foot space. Two years later, they were in a 12,000 square foot space and have continued their rapid growth.

Powder Coating and Fusion Bonded Epoxy Coating

With his son, Adam, as Vice President and General Manager, ABQ Manufacturing has a staff of nine full-time employees that ramps up quickly with temp workers when they get busy and need to add more shifts.

With his son, Adam, as Vice President and General Manager, ABQ Manufacturing has a staff of nine full-time employees that ramps up quickly with temp workers when they get busy and need to add more shifts.

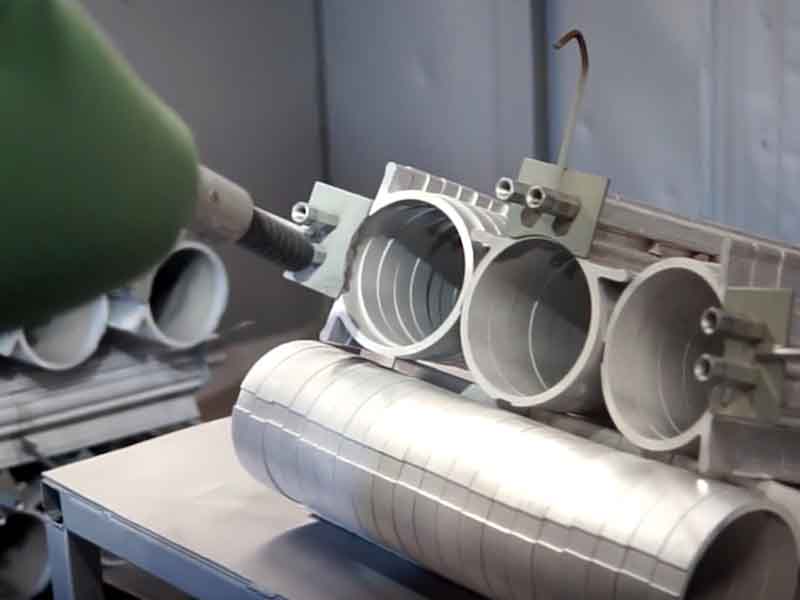

They do powder coating and fusion bonded epoxy coating on a wide variety of substrates, with their pretreatment capabilities including abrasive blast, iron phosphate, and zirconium conversion coating.

“We also have a small fab shop where we can quickly build custom fixtures for hanging parts,” Adam says. “We have a few customers who have us do small fabrication jobs for them.”

Bruce says ABQ Manufacturing serves a wide variety of industries, everything from sheet metal and machined electronic enclosures to architectural products such as gates, fence panels, rails, and stairs to sculptures.

“We have a customer who builds and installs pumps for municipal water systems throughout the region,” he says. “We apply fusion bonded epoxy to their pump components.”

Adding Line to Coat Heat Sensitive Substrates

Adam BellThe facility is planning to add a line to coat heat-sensitive substrates such as wood, Bruce says, which gives them an even bigger advantage to attract more customers.

Adam BellThe facility is planning to add a line to coat heat-sensitive substrates such as wood, Bruce says, which gives them an even bigger advantage to attract more customers.

“We are excited about adding the capability to coat wood substrates,” he says. “I believe it will be a big part of our business in the future.”

Their operation is very detail-oriented, Adam says, owing to it having a great crew who are conscientious about producing an excellent quality product.

“About 97% of our jobs are delivered on time or early,” he says. “We communicate well.”

ABQ Manufacturing’s top suppliers for powder materials are Cardinal, Tiger Drylac, Sherwin Williams, IFS, TCI, Axalta, 3M, Vitracoat, and Prismatic. For pretreatment chemicals, they utilize Lincoln Chemical.

“We use Gema guns, and we buy gun parts and have gun repairs done by First in Finishing,” Adam says. “IDS Blast supplies parts for our blast room.”

Steady Growth from Word-of-Mouth

Bruce says business has been steadily growing for the shop and that they do some print advertising as well as an email to generate leads. But he says most customers come to them through word-of-mouth or from a Google search.

Bruce says business has been steadily growing for the shop and that they do some print advertising as well as an email to generate leads. But he says most customers come to them through word-of-mouth or from a Google search.

“As far as retaining customers is concerned, we deliver what our customers need when our customers need it,” Bruce says.

Case in point: when ABQ Manufacturing upgraded its website last year, the marketing company had Bruce ask their customers to post reviews on Google. He says it was very gratifying to see the wonderful things their customers have to say about them.

“After 45 years in the metal finishing industry, I still enjoy coming to work every day and dealing with our employees and with our customers,” Bruce says. “And I am also very fortunate to work with my son every day.”

Visit https://www.abqmfg.com