Powder coating applicators can maximize profits by eliminating excess coating materials.

The easiest way to streamline an operation and improve ROI is to monitor powder coating film thickness with a measurement gauge. A too thin coating can lead to performance and longevity issues, while too much material can affect appearance and is a waste of resources. By measuring powder coating thickness, there is a reduction in waste and increase in the control of operations and material costs.

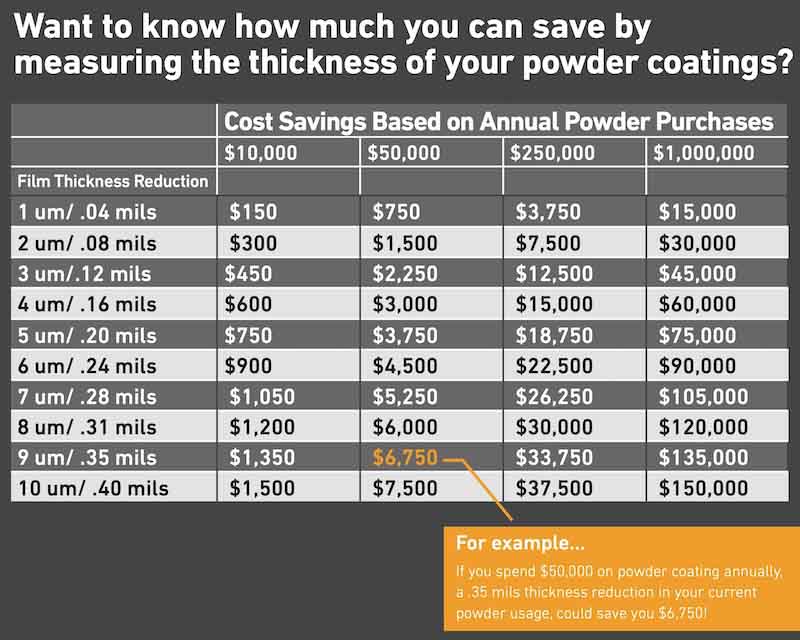

With this in mind, it’s crucial that the gauge to monitor coatings takes accurate, precise, and repeatable measurements. Material thickness of just half a mil can have the potential to cost thousands of dollars.

Time = Money

An easy to use gauge guarantees that the time training employees on how to use the instrument is short and productive. Everyone from the booth operator to the owner should be able to learn how to operate the gauge quickly.

An easy to use gauge guarantees that the time training employees on how to use the instrument is short and productive. Everyone from the booth operator to the owner should be able to learn how to operate the gauge quickly.

Another important feature to look for in a gauge is LED light indicators that remove the need to watch a screen while measuring. It makes an enormous difference determining if a measurement is in or out of spec with just the flash of a green or red light. The hand not in use remains free, improving safety of the operator, and again saving valuable time. A handheld gauge has the potential to improve the efficiency of your operation in multiple areas. Choosing the instrument that fits your process is the first step to saving time and improving quality.

Fits In Your Pocket

A gauge that fits in a pocket and can be brought directly to the part for measurements is crucial for safety and efficiency. Bulkier gauges require careful maneuvering, increasing the chances of being dropped or broken. While these larger instruments are necessary for some applications, a powder coating operation thrives on the ability to quickly test for coating thickness directly on the shop floor.

Another benefit to one handed operation is the user’s ability to use his/her free hand to balance or position the parts for more accurate testing. This ability saves the user time and reduces the chances of safety hazards that are apparent with larger instruments in this specific environment.

Using a gauge right on the production line guarantees the same quality standards on both small and oversized parts. Some helpful tips:

- Monitoring powder coating thickness with a handheld gauge helps to reduce operational cost by lessening wasted materials

- A measurement gauge with LED light indicators makes it easy to know when the coating thickness is in or out of spec, saving time.

- Quickly improve the quality process with an instrument that is small and can easily be transported from small to large parts.

- Happy customers are returning customers. Meeting customers’ specifications, and easily generating branded reports helps business in the long run.

- For example, Fischer’s MP0R has all the important qualities listed and is the first step toward a simpler, faster and cost saving quality process solution.

Customers’ Expectations and Quality Standards

Reporting is an essential step in improving relationships with customers and building trust. Customers want to know that they are receiving the highest quality product for the best price. In order to meet these needs, an efficient and informative reporting software is an easy step to add to the quality process. Look for a gauge that allows quick reporting, sent in a simple format, directly to an email address.

Reporting is an essential step in improving relationships with customers and building trust. Customers want to know that they are receiving the highest quality product for the best price. In order to meet these needs, an efficient and informative reporting software is an easy step to add to the quality process. Look for a gauge that allows quick reporting, sent in a simple format, directly to an email address.

Instruments with superior repeatability precision allow for reliable measurements. Utilizing certified foils to adjust and verify gauge accuracy vs. non-precise shims will provide the trueness necessary to monitor and adjust a powder coating line properly.

Meeting industry standards is one more tool you can use to build trust with your client base and improve your company’s quality process. Give your current and potential customers the peace of mind, knowing that their products are in capable hands.

Visit www.fischer-technology.com

About Fischer

One gauge that meets all these requirements and more is the MP0R. The handy, gauge is ideal for fast and easy thickness measurement of paint layers on ferrous and non-ferrous metals, even aluminum. Thanks to its wide measuring range up to 100 mils, it is perfect for very thick coatings. Fischer is known for precise instruments designed with German engineering. The MP0R benefits from Fischer’s over 60 years of knowledge in the development of coating thickness gauges, and has the latest features that powder coater’s need today. It’s time to ensure that the quality of the products provided to your customer exceed in every step of your quality process by investing in the MP0R from Fischer. Features

- Automatically recognizes the substrate material

- Broad measurement range (0 – 100 mils)

- Modes for single-point and continuous (free running) testing with up to 70 measurements per minute

- An LED on the probe indicates when tolerance limits are breached

- Data analysis with the Fischer app for smartphone or tablet

- Potentially damaged areas can be documented with photos in the reports

- Bluetooth connection to mobile devices

- Due to its robust housing, even under harsh environmental conditions the gauge remains extremely reliable