The toxic effect of hexavalent chromium compounds has been known for a long time and has led to extensive bans on these substances in recent years.

Stefan LenzerCommon to all regulations is the ban and strict restriction of conversion coatings containing chromium VI, as they were used on aluminum and other metals for years. A ban for the European construction industry is expected in the foreseeable future.

Stefan LenzerCommon to all regulations is the ban and strict restriction of conversion coatings containing chromium VI, as they were used on aluminum and other metals for years. A ban for the European construction industry is expected in the foreseeable future.

Over the last 20 years, numerous chrome VI-free alternative products for the pre-treatment of aluminum were developed by chemical and system suppliers. As a possible pre-treatment before powder coating of aluminum, most of these alternative products show equivalent performance compared to the systems containing chrome VI. The so-called no-rinse or dry-in-place processes are the most frequently encountered chromium-free processes.

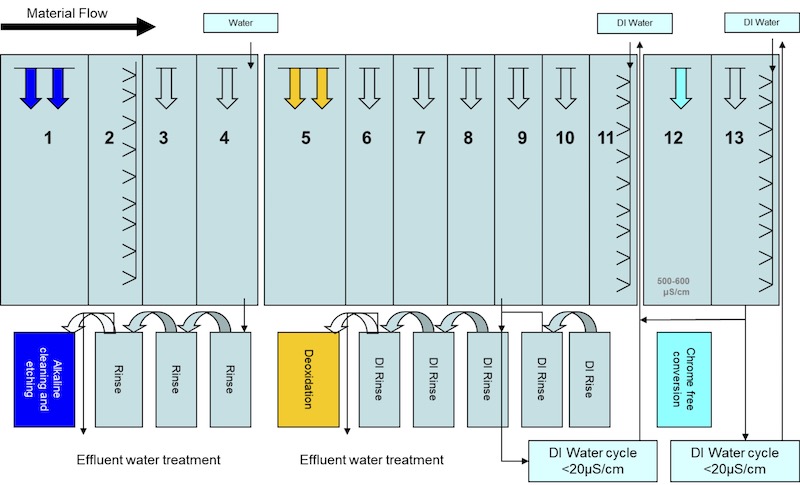

Figure 1 shows a typical vertical line. Photo courtesy Surface Aluminium Technologies Srl; SAT - Surface Aluminium Technologies Srl; www.sataluminium.comHowever, these have some disadvantages in practice which should not be ignored. During the drying process of the applied conversion coating, the undesirable formation of "last drops" can occur. This can lead to visual defects after powder coating and may require introducing a final spray rinse after all. Furthermore, the processes currently used are not operated as a long-life bath due to "polymer ageing“ and have to be completely or partially renewed at regular intervals in an overflow process known as bleed & feed.

Figure 1 shows a typical vertical line. Photo courtesy Surface Aluminium Technologies Srl; SAT - Surface Aluminium Technologies Srl; www.sataluminium.comHowever, these have some disadvantages in practice which should not be ignored. During the drying process of the applied conversion coating, the undesirable formation of "last drops" can occur. This can lead to visual defects after powder coating and may require introducing a final spray rinse after all. Furthermore, the processes currently used are not operated as a long-life bath due to "polymer ageing“ and have to be completely or partially renewed at regular intervals in an overflow process known as bleed & feed.

The Iridite EXD process presented below was developed by MacDermid Enthone as a 1-component, chromium-free, polymer-free system based on zirconium. The conversion coating produced with Iridite EXD by immersion, spraying or flow coating is suitable for the treatment of aluminum and for hot-dip galvanised steel. For the use prior to aluminum powder coating, Iridite EXD has Qualicoat (A-045) and GSB (249b) approvals.

Process Description

Pre-Treatment

The pre treatment is of decisive importance for the performance of alternative conversion processes on aluminum. It must be adapted to suit the types of alloys to be treated. Fundamentally, the pre-treatment must produce a clean, grease- and oil-free, deoxidised surface. The water wettability of the surface thus produced is particularly important. In the case of aluminum, the microcrystalline deformation layer underneath the oxide layer must be removed as a possible initiator for filiform corrosion. Highly alkaline degreasing/etching or acidic etching degreasers are used to clean the substrate and achieve an initial etch. Subsequent deoxidation removes the alloying components, such as Zn, Fe, Mg or Si, that were exposed or remained on the surface after the alkaline etching process. The deoxidization step also leads to further etch removal, which is usually less than in the first alkaline process stage.

The pre-treatment sequences below describe two of the possible process sequences for the application of Iridite EXD:

|

Short process cycle using acid cleaning/etching and deoxidation: |

Combined alkaline and acid cleaning/etching and deoxidation: |

|

1.Acid Etch/Deoxidising |

1.Alkaline cleaning / etching |

|

2.Rinsing (Best Available Technology) |

2.Rinsing (Best Available Technology) |

|

3.DI Rinsing (Recommended Conductivity< 20 µS/cm) |

3.Acid Etch/Deoxidising |

|

4.Iridite EXD |

4.Rinsing (Best Available Technology) |

|

5.DI Rinsing (Recommended Conductivity< 20 µS/cm) |

5.DI Rinsing (Recommended Conductivity< 20 µS/cm) |

|

6.Iridite EXD |

|

|

7.DI Rinsing (Recommended Conductivity< 20 µS/cm) |

Conversion Coating Formation

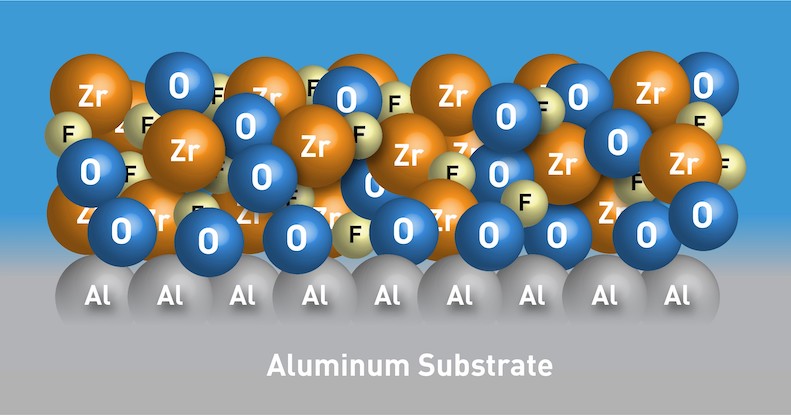

The fluorides contained in Iridite EXD serve as activators for the aluminum surface during layer formation. The layer formation takes place during the contact time between the process chemistry and the metal surface at a pH value of approx. 4. The mechanism of paint adhesion and corrosion protection from Iridite EXD is based on the permanent adhesion between the coating and pre-treated substrate. Without this bond, influences of humidity, heat and salts would negatively affect the adhesion of the coating and lead to corrosion at an early stage. Iridite EXD forms a layer consisting of mixed oxides (Fig. 2) which, in addition to aluminum, also contains amounts of zirconium. Iridite EXD, however, is completely free of organic compounds.

Figure 2: Schematic conversion layer representation.

Figure 2: Schematic conversion layer representation.

Application

The conversion coating process works with the application parameters listed in table 1. The same product chemistry is used for make-up and maintenance.

Tab. 1: Application parameters Iridite EXD

|

Parameter |

Recommended Value |

|

Iridite EXD |

1 – 3% v/v |

|

Temperature |

28 – 32°C (82 - 90°F) |

|

Treatment time |

20 – 30 Seconds |

|

pH-Value |

4.5 – 5.3 |

The application is carried out by immersion, spray or flow coating. Figure 3 shows a practical example of a vertical line. A short process setup that eliminates alkaline degreasing and pickling is also possible. A small amount of deionised water is used for the final rinse after the conversion coating formation. Since the Iridite EXD rinse water does not contain any interfering polymers, it is possible to run the rinses before and after conversion coating in a close loop system and achieve an almost 100% recycle rate. Rinse water of the final rinse can be used to feed the rinse before the Iridite EXD active bath to achieve a required conductivity of less than 20 µS/cm

Combined with an almost infinite life of the Iridite EXD conversion coating process, it is possible to operate at Zero Liquide Discharge levels, as demonstrated at many existing accounts. MacDermid’s own waste water treatment division, MacDermid Envio Solutions, can help with the design and implementations of such technology.

The long bath life is possible through the higher operating pH value of pH 4 in the Iridite EXD process. Automatic dosing of the Iridite EXD process chemistry according to pH or conductivity will guarantee consistent quality and low operating cost. Should it become necessary to dispose of the bath solution, simple wastewater treatment by means of neutralisation is sufficient.

Figure 3: Practical process example of a vertical plant combining alkaline and acid pre-treatment.

Figure 3: Practical process example of a vertical plant combining alkaline and acid pre-treatment.

Performance Criteria of Existing Installation

Physical Properties of the Conversion Layer

In contrast to the gold-yellow and easily recognizable layer coloration of classic yellow chromates, the conversion layer produced by Iridite EXD is almost colorless. The generated layer has a layer weight of 0.03 - 0.1 g/m², which is determined by means of a dissolution/strip method and a subsequent photometric zirconium analysis.

Properties of the Powder Coated Conversion Layer

In addition to the treatment of aluminum profiles and sheet metal, Iridite EXD is also suitable for aluminum castings and hot-dip galvanised steel components. The pre-treatment has to be suitable and needs to adapted for each individual application. The results of the Qualicoat and GSB approval tests meet the high-quality requirements and testify to the unrestricted usability in this segment. The conversion coating produced with Iridite EXD is characterized by its temperature stability. Drying temperatures of up to 180 °C in the dryer are possible without impairing the performance of the conversion coating. The possible increase of the drying temperature in the adhesive water dryer accelerates the drying.

Summary and Outlook

Iridite EXD is a chrome-free, inorganic process for the pre-treatment of aluminum and its alloys before powder coating and has proven itself in industrial use since 2006. The conversion coatings produced during the spraying or immersion process are characterized by their temperature stability. The process has been approved by the Quality Association Qualicoat and the GSB for the alternative pre-treatment of aluminum before powder coating in the construction industry and is already in use in numerous, well-known finishing companies. The process developed by MacDermid Enthone is a reliable process that provides excellent corrosion protection on aluminum. Users of the Iridite EXD process have a technically proven, globally available, and very economical process at their disposal.

Stefan Lenzer is the Global Product Line Director Light Metal Finishes at MacDermid Enthone Industrial Solutions

Sources:

- GSB International, Schwäbisch Gmünd; www.gsb-international.de

- Qualicoat, CH-Zürich; www.qualicoat.net

- MacDermid Envio Solutions; www.macdermidenvio.com

- MacDermid Enthone, Industrial Solutions; www.industrial.macdermidenthone.com