As a new owner of a company, you never want to find out that the wastewater system is not operating within its design parameters.

Especially when you have plans to expand operations by adding larger process tanks and new processes to offer customers, and that is exactly where the new owner of one electropolishing company found themselves, however. With a need to get the wastewater system up to par, they contacted their Hubbard-Hall rep for assistance.

Robin DealWhen the Aquapure Team made the first site visit, it was obvious the system needed some work. A treatment plan needed to be determined for the rinses from the electropolishing and passivation processes that could work within the existing 1000-gallon batch system. Pumps, mixers, and dewatering equipment would need to be replaced. A wastewater pretreatment discharge permit would need to be renewed with the city’s approval of the new treatment plan. While all of this may seem overwhelming, the Aquapure Team had no doubt that this system could be up and running in no time.

Robin DealWhen the Aquapure Team made the first site visit, it was obvious the system needed some work. A treatment plan needed to be determined for the rinses from the electropolishing and passivation processes that could work within the existing 1000-gallon batch system. Pumps, mixers, and dewatering equipment would need to be replaced. A wastewater pretreatment discharge permit would need to be renewed with the city’s approval of the new treatment plan. While all of this may seem overwhelming, the Aquapure Team had no doubt that this system could be up and running in no time.

The first step was to contact the city to see if there would be any changes to the pretreatment discharge permit. With the go-ahead from the city to work with the previous permit’s limits, the Aquapure Team could begin working on the treatability study. A treatability study starts with determining what is in the wastewater that needs to be removed, what coagulant and flocculant work best to remove the contaminants, where the best pH range to achieve the optimum removal needs to be, and what type of equipment is needed to complete the treatment.

|

pH |

1.42 |

|

Total Suspended Solids. |

149mg/L |

|

Turbidity |

47FAU |

|

Lead |

1.4mg/L |

|

Copper |

211mg/L |

|

Zinc |

17mg/L |

|

Nickel |

71mg/L |

|

Chrome |

258mg/L |

Multiple bench tests were completed on the wastewater streams. Two treatment options were identified as acceptable options.

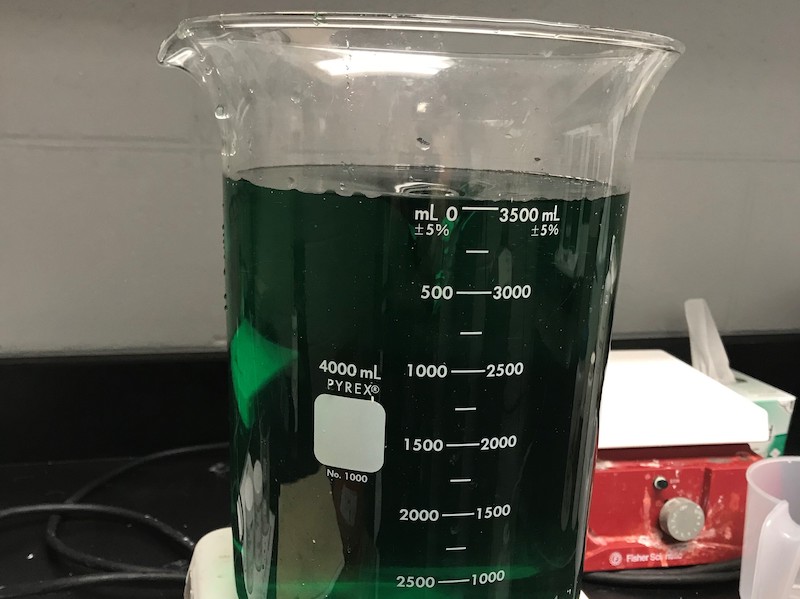

Treatment Plan A was to use pH adjustment with sodium hydroxide and a combination of 2 clay blends, Aquapure Quick Drop 631 and Aquapure Quick Drop 651. The first step was to adjust pH up to 9 with the sodium hydroxide. Equal parts of the Aquapure Quick Drop 631 and the Aquapure 651 were added. Clay blends need 2 things to work properly, time and rapid mixing. When bench testing, this translated to creating a vortex within the beaker, then slowly sprinkling in the clays and allowing them to blend for 30 minutes to open and absorb the contaminants.

Treated Electropolish wastewater

Treated Electropolish wastewater

|

pH |

8.8 |

|

Total Suspended Solids. |

5mg/L |

|

Turbidity |

4FAU |

|

Lead |

0.403mg/L |

|

Copper |

0.152mg/L |

|

Zinc |

0.101mg/L |

|

Nickel |

0.452mg/L |

|

Chrome |

0.639mg/L |

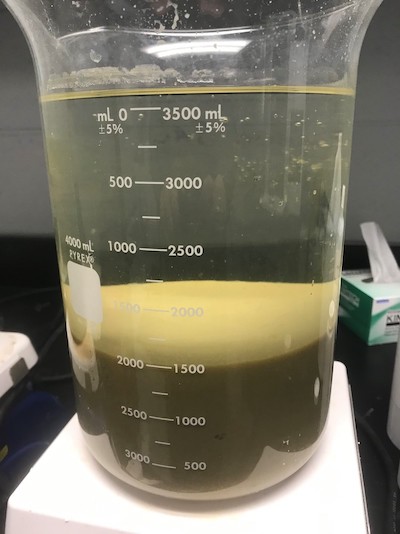

Treatment Plan B was to use a liquid coagulant Aquapure Cal 40, pH adjustment using sodium hydroxide, and a ready to use anionic polymer Aquapure AN Clear. In bench testing, this means adding the Aquapure Cal 40 while the sample was blending before adjusting the pH to the desired range. This allows the proper hydroxide bonds to form between the coagulant and the metals that need to precipitate out. The pH was adjusted up to 9 with the sodium hydroxide. This saw the formation of the metal hydroxide salts, otherwise known as pin floc. With the addition of the Aquapure AN Clear, a ready-to-use anionic flocculant, floc formed immediately and settled rapidly.

|

pH |

9.0 |

|

Total Suspended Solids. |

3mg/L |

|

Turbidity |

0FAU |

|

Lead |

0.203mg/L |

|

Copper |

0.092mg/L |

|

Zinc |

0.087mg/L |

|

Nickel |

0.365mg/L |

|

Chrome |

0.398mg/L |

While the bench testing was being completed, system recommendations were made. The first recommendation was for a pump to dose the sodium hydroxide and a pH meter/probe to ensure the pH was correct for treatment. Second, dewatering equipment was needed. With space constraints, and a need to not spend a ton of time on the dewatering aspect, an indexing filter was recommended for dewatering. Indexing filters allow the sludge to dry using the power of gravity, draining the water from the solids. The longer the solids sit in the filter bed, the drier they become. Upon completion of the bench-testing, options for dosing both the clays and the liquid coagulant and flocculant.

Both treatment options were present to the city. With the city’s approval, trials were run on both treatment plans. The Aquapure Cal 40 and Aquapure AN Clear treatment plan was proven to be the best option for this facility. With the wastewater system running, the plans to expand were now able to be completed by this new electropolishing company’s owner.

Robin Deal is Product Leader, AquaPure/Wastewater Treatment Specialties. Visit www.hubbardhall.com