Hexavalent chrome set the gold standard for corrosion protection on aluminum, particularly in aerospace and defense applications.

CHEMEON Surface Technology Touch-Up PensIt worked exceptionally well—but at a high cost to worker safety and environmental health. As regulations tightened and awareness of its carcinogenic risks grew, the metal finishing industry faced a difficult challenge: how to replace a proven technology without compromising performance, reliability, or mission readiness.

CHEMEON Surface Technology Touch-Up PensIt worked exceptionally well—but at a high cost to worker safety and environmental health. As regulations tightened and awareness of its carcinogenic risks grew, the metal finishing industry faced a difficult challenge: how to replace a proven technology without compromising performance, reliability, or mission readiness.

Chemeon Surface Technologies has spent more than a decade answering that question.

Under the leadership of President Ted Ventresca, Chemeon has become a leader in conversion coatings that replace hexavalent chrome with safer, high-performance trivalent and zero-chrome alternatives. The company’s work—much of it rooted in Department of Defense (DoD) research and real-world military requirements—has not only reshaped specifications but also introduced practical innovations that resonate on the shop floor and in the field.

“We’ve become a global leader in conversion coatings that replace the known carcinogen hexavalent chrome,” Ventresca says. “We are the safe alternative to trivalent chromes, and we also have some zero-chrome solutions as well.”

From Navy Patent to Industry Standard

Chemeon’s origins are tightly linked to the U.S. military’s need for a safer corrosion-protection technology. Hexavalent chrome had been used successfully for more than 80 years, particularly on aluminum aircraft structures, but its health risks made long-term reliance unsustainable.

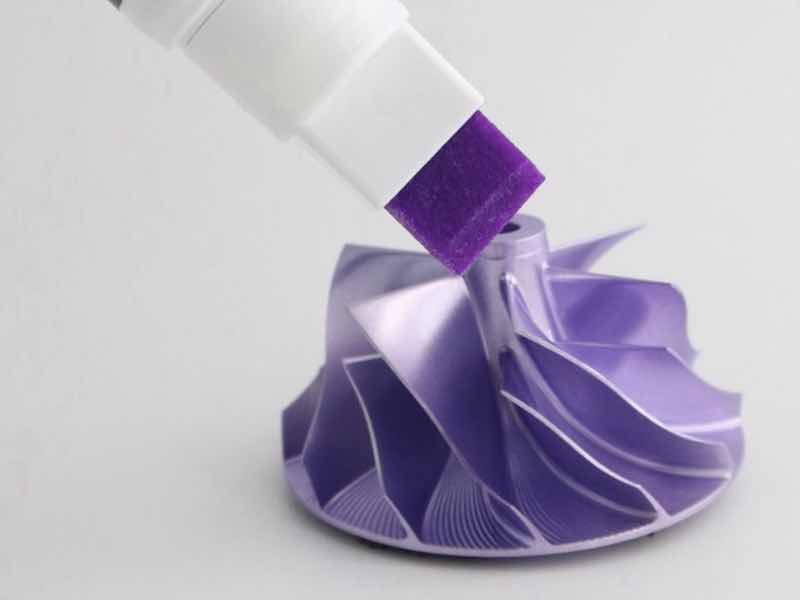

“It’s a colorized trivalent with superior performance on existing trivalents, and it provides our signature Chemeon purple-violet color.”

Chemeon was the first company to commercialize a U.S. Navy–developed patent known as TCP (trivalent chrome pretreatment). The technology—originally developed for military aircraft—became a clear trivalent coating that delivered robust corrosion resistance without the hazards of hexavalent chrome.

“Our Dr. Sjon Westre was actually the first to commercialize that technology,” Ventresca says. “From that point, TCP became an industry standard that’s been used since the early 2000s.”

TCP was a major step forward, but it also revealed an unexpected challenge—one that had nothing to do with chemistry and everything to do with human factors.

Why Color Matters in Conversion Coatings

For more than 70 years, applicators relied on the distinctive yellow-gold hue of hexavalent chrome as a visual cue. That color told operators—many of them artisans rather than scientists—that the part was fully coated and protected.

“When you take that color away, you take away a critical visual confirmation,” Ventresca says. “The applicator needs to see that the part is completely coated.”

Clear trivalent coatings performed well, but they lacked that immediate, intuitive feedback. Recognizing this gap, Chemeon invested years of development to create a colorized trivalent solution that met or exceeded existing performance standards while restoring visual confidence on the line.

“You’re actually getting in touch with the inventors of the technology itself,” Ventresca says. “That relationship is a key differentiator.”

The result was ETCP—Enhanced Trivalent Chrome Pretreatment.

“We patented ETCP,” Ventresca says. “It’s a colorized trivalent with superior performance on existing trivalents, and it provides our signature Chemeon purple-violet color.”

That distinctive color has become a hallmark of Chemeon’s technology, offering instant confirmation that the coating has been properly applied—much like hexavalent chrome once did, but without the associated risks.

Performance Where It Matters Most

Replacing hexavalent chrome is not simply a regulatory exercise, particularly in aerospace and defense. Aircraft skins, helicopters, and military vehicles operate in some of the harshest environments imaginable—salt spray, sand, humidity, and extreme temperature swings.

“If something has worked like hexavalent chrome, you really don’t want to switch off until you find something that really works,” Ventresca says.

ETCP was designed to meet that standard. It is qualified under key military specifications, including MIL-DTL-81706 and MIL-DTL-5541, and delivers strong corrosion performance on demanding alloys such as 2024 aluminum.

“This fills an unmet need. Whether it’s an MRO facility or field repair, this is where the demand for a compact kit came from.”

Just as important, Chemeon emphasizes direct technical support.

“You’re actually getting in touch with the inventors of the technology itself,” Ventresca says. “That relationship is a key differentiator.”

That collaborative approach has paid dividends. In a recent development highlighted by FinishingAndCoating.com, the U.S. Army Missile Command formally adopted and recommended ETCP for touch-up and repair applications across its global network of depots and bases. The recommendation is specifically tied to Sikorsky Black Hawk and Lockheed Martin Apache helicopter platforms.

“It’s a really wonderful relationship that we’ve developed with the DoD,” Ventresca says. “But that extends to industry as well.”

Solving the Touch-Up and Field Repair Challenge

While full conversion coating lines address new parts and overhauls, real-world assets rarely operate under ideal conditions. Aircraft and vehicles are nicked, abraded, and exposed to galvanic corrosion during service. Often, a complete strip-and-recoat is impractical—or impossible.

While full conversion coating lines address new parts and overhauls, real-world assets rarely operate under ideal conditions. Aircraft and vehicles are nicked, abraded, and exposed to galvanic corrosion during service. Often, a complete strip-and-recoat is impractical—or impossible.

That reality drove Chemeon to develop its Surface Touch-Up Repair Kit.

“When you think about helicopters operating over salt water, or vehicles in sand and coastal air, those are harsh environments,” Ventresca says. “You don’t always need a complete refurbishment, but you do need to touch up damage to maintain structural integrity and asset life.”

Chemeon’s touch-up solutions evolved from earlier ETCP pens and wipes used by the military and industry. The current kit is compact, self-contained, and designed for both depot-level maintenance and true field repair.

“This fills an unmet need,” Ventresca says. “Whether it’s an MRO facility or field repair, this is where the demand for a compact kit came from.”

Designed for Real-World Use

Ease of use was a core design requirement. Chemeon intentionally engineered the kit to be used by technicians without advanced materials science training.

“We don’t assume the user is a chemist,” Ventresca says. “They’re an artisan on the line or in the field.”

“The compact nature of the kit makes it self-contained. It can fit under a seat or in a storage compartment.”

The kit includes cleaning wipes with isopropyl alcohol, surface-preparation materials, gloves, and the ETCP solution, which can be applied by wipe or brush—both of which are Method B applications under military specifications. Clear instructions and tutorial videos guide users step by step, reducing variability and improving confidence.

“Our videos have really been heralded as a great asset,” Ventresca adds.

The result is a process that can be performed on-site, without shipping parts back to a centralized facility—a critical advantage for mission-critical equipment.

Expanding Beyond Defense

Although the Surface Touch-Up Repair Kit was developed in response to a U.S. Marine Corps requirement, its appeal extends well beyond military platforms.

Although the Surface Touch-Up Repair Kit was developed in response to a U.S. Marine Corps requirement, its appeal extends well beyond military platforms.

“We’ve found a great need in the general aviation market,” Ventresca says.

Privately owned aircraft, rental fleets, and light aviation platforms face similar corrosion challenges but often lack access to specialized finishing facilities. Chemeon plans to make the kit more widely available in 2026 through general aviation channels, in addition to direct sales.

“The compact nature of the kit makes it self-contained,” Ventresca explains. “It can fit under a seat or in a storage compartment.”

The same logic applies to land vehicles, where exposure during both operation and storage can degrade coatings over time.

“When vehicles are sitting, they can still be attacked by sea air, sand, or moisture,” Ventresca notes. “That’s why something like this is such a valuable addition to maintenance and field repair.”

Innovation with Purpose

Innovation in corrosion protection tends to be evolutionary rather than revolutionary—and for good reason. When lives and multi-million-dollar assets are at stake, consistency matters.

But Chemeon’s work demonstrates that innovation is still possible when real-world needs drive it.

“Corrosion protection is so key and so important,” Ventresca says. “You have to maintain what works—but there are exciting things on the horizon.”

As the industry continues its transition away from hexavalent chrome, Chemeon’s combination of performance, safety, and practical usability positions it as a critical partner for finishers, MROs, and OEMs alike.

For an industry that values both tradition and trust, that may be the most important coating of all.

Visit https://chemeon.com.