Simple as they might seem, the hoses and pumps of your application and fluidizing equipment are some of the most important parts.

If they do not work properly, break, or are contaminated, the whole system goes kaput – likely leaving you with a reject at the end of a job.

Within this guide, we will be going over some great tips for the care and maintenance of hoses and pumps, as well as covering some of the main issues that can appear.

Pumps

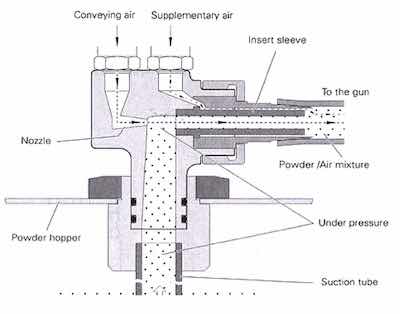

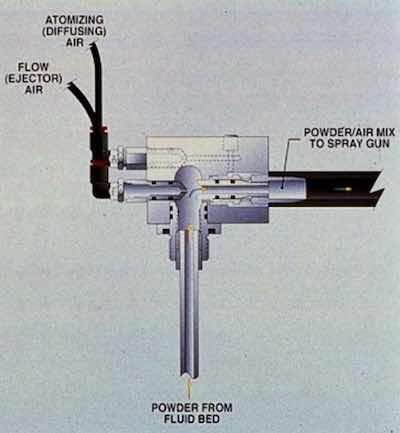

Fiona Levin-SmithThe main type of pumps used today for powder coatings are Venturi pumps, and pumps are sort of like the heart of your equipment. They blow air across the top of the pickup tube, which creates a negative pressure. In addition to the powder feed air, there is an atomizer which mixes additional air into the powder being conveyed through the hoses and aids in a consistent flow. Now, what the pumps do is basically control the ratio of powder feed air to atomized air.

Fiona Levin-SmithThe main type of pumps used today for powder coatings are Venturi pumps, and pumps are sort of like the heart of your equipment. They blow air across the top of the pickup tube, which creates a negative pressure. In addition to the powder feed air, there is an atomizer which mixes additional air into the powder being conveyed through the hoses and aids in a consistent flow. Now, what the pumps do is basically control the ratio of powder feed air to atomized air.

Maintenance

Putting it simply, pumps need to be maintained frequently and consistently. Depending on how much you use them, the various parts pumps are made of will wear – and faster than you think too. A good habit to get into is to check over the wear parts every day, as powder is abrasive. Better to find any problems at the start of a shift than for it to crop up in the middle of an application. Gun surges, gun spits, and inconsistent flow are some of the issues that can occur because of a faulty or broken pump. Best to avoid them, right?

Common Issues: Impact Fusion

If your pressure levels are too high, you may encounter a problem known as impact fusion. Basically, inside of the pump powder starts to build up. As it builds up, the air powder flow will become restricted. (At this point many people will turn up the feed pressure, which only worsens the problem.) As the impact fusion worsens problems such as gun spits and surges can occur. Most manufacturers will have some sort of gauge that will let you know when it is time to replace a wear part. Be sure to check your manufacturers guidelines for when and how to check for wear.

Pick-up tubes are another part that should, like pumps and hoses, be checked for wear and tear on a regular basis. The O-rings, in particular, must be given regular maintenance because if they are damaged or torn extra air will be pulled in; which can cause a number of problems, including gun spits and surges.

Another way that you can control, or even avoid, impact fusion is to reduce the air pressure settings of the guns and transfer pumps. Transfer pumps are used in reclaim systems to move air and powder through and back towards a feed hopper, and just like their cousins, transfer pumps require regular maintenance.

Moisture in the air supply or in the environment can also cause impact fusion. As we’ve covered previously, powder is hygroscopic, meaning that it will pull moisture in from the air if it is there. Once that moisture is on the powder, it starts to form clumps that will grow bigger and bigger, and possibly even start to clog up the hoses, guns, and pumps. To keep moisture from the air supply, install additional coalescing filters, and an air chiller as extra insurance. Finally, if you can, control the amount of moisture in the environment of the application room via the air conditioning system; humidity is what creates moisture in the air, so keep things dry and cool.

Sometimes in transit powder can compact and almost clump together. Breaking the powder up beforehand will help the box feeder create a smooth flow of powder. You can do this nice and simply by lightly rolling the bag of powder around or running the powder through a 60 mesh screen, before then popping it back in the box.

Other Issues

There are a few little things that can build up into one, big problem. Like if the fluidizing membrane gets water in it and the fluidization is poor, the pickup tubes and pumps will start to create a void in the fluidized powder inside the hopper. Once that void collapses, you’ll get gun surges and spits – sort of our go-to bad guy for this guide.

There are a few little things that can build up into one, big problem. Like if the fluidizing membrane gets water in it and the fluidization is poor, the pickup tubes and pumps will start to create a void in the fluidized powder inside the hopper. Once that void collapses, you’ll get gun surges and spits – sort of our go-to bad guy for this guide.

Proper maintenance is really the only way to avoid all of these problems. So, make sure checking pumps and hoses, especially wear parts, is on your daily maintenance list and check it twice.

Knowing how your equipment functions is a good way to avoid making a silly mistake, like mixing up your powder feed with your atomized air feed. Also, when cleaning pumps, you might want to get into the habit of disconnecting the air lines connected to them. If powder is accidentally blown back up into the controllers or valves, the lifespan of the equipment will be reduced.

Hoses

Hoses are literally just the hoses that carry the fluidized powder from the pump to the gun. Over the years, hoses have been modified to perform better. Where hoses were once made of synthetic rubber, they are now often made of a form of conductive plastic. This reduces the amount of static charge that a powder can pick up as it moves through the tubes. The addition of a conductive strip, or wire, redirects what static charge does build up towards the grounding of the hopper.

Hoses are literally just the hoses that carry the fluidized powder from the pump to the gun. Over the years, hoses have been modified to perform better. Where hoses were once made of synthetic rubber, they are now often made of a form of conductive plastic. This reduces the amount of static charge that a powder can pick up as it moves through the tubes. The addition of a conductive strip, or wire, redirects what static charge does build up towards the grounding of the hopper.

On a typical powder gun you will generally have two controls, one for the powder feed, and one for the atomizing. Depending on how you set everything up, these settings will allow you to have a stream of powder, or a consistent flow of powder, from the fluidizing hopper through the hoses to the gun.

Maintenance

Like pumps, hoses require consistent maintenance. They also require cleaning in between jobs – that is, if you are changing colors or chemistries. Say you were spraying a red, and then a clear topcoat. In between jobs, the hoses, pump, gun and such should be cleaned to avoid contaminating the powder. At IFS Coatings, we would even recommend having different sets of hoses for light colors, dark colors, and different chemistries. Hoses can be expensive, but so too can having to redo a job because of a reject.

Now, not all hoses are the same. Some are made from different materials and depending on what the chemistry of your powder is you may need to use different types of hoses (by this, we mean that the hoses are physically made of). For example, fluoropolymers will turn into a semi-solid state in certain types of hoses – like vinyl – and will start to build up inside the hose itself. If you ever run into an issue like this, talk to the manufacturer of both the powder and the equipment.

If you ever need to replace a hose, we truly recommend that you buy said replacement/s from the people that manufacture the equipment you use. Sometimes, different brands just are not compatible.

Common Issues: Length

You do not want too much of a hose run. The longer a hose is the more chances there are for things to go wrong, and the more power and pressure you need to move an even flow of powder through it. Keep your hoses to a maximum length of 25 feet where possible.

Do not just pick up a hose and jump right into spraying the substrate, especially if the hose is on the longer side. See, powder has just been sitting in that hose, perhaps some will even have sunk to the bottom, so when you turn it on for the first time there will be a huge surge of powder. Point the gun away from the substrate until the air and powder regulates itself to a smooth flow. Easy done!

Constricted Hoses

It is actually pretty easy to strangle the powder flow and air supply in a hose, even by stepping on it. Sometimes the damage is permanent too. This damage can be caused by bending the hose to the point where it kinks, stepping on it, or laying/rolling equipment over it. This is especially common when job shops spray by hand; a wayward foot or bending the hose to do the underside of a substrate can do more damage than some people realize.

But what does a constricted hose actually cause? Gun spits, for one. Surges, for another. The best way to avoid these problems is to just be spatially aware during an application. That is if it isn’t already second nature! Otherwise, keep your hoses free and clear of other equipment.

If your job shop uses non-conductive hoses, your applicator must be careful about the hose coming in contact with any metallic surfaces – like a stray piece of metal on the ground – as this will cause arcing. The static charge that powder gathers as it moves through the hose will literally arc to that metal, possibly even burning a hole through the hose. Either keep a sharp eye for metal on the ground or swap your hoses for conductive ones.

Final Tips

Typically, when an issue with pumps or hoses occurs, what you will see are gun surges and spits. From there, diagnosing the problem is a simple process of elimination. First, check if your powder feed and atomizing settings are dialed in right. Second, be sure that your hoses aren’t kinked or constricted. Third, see if there is a steady flow of powder coming out of the gun, and adjust the powder to air ratio if needed. Fourth, if you hadn’t already, check the wear parts inside of the pump. And fifth, dig around for any signs of impact fusion inside the pump. If you still haven’t found the problem, it might be time to call your manufacturer.

As for those final tips ...we have two great ones to finish up this guide with!

One: preventative maintenance is our motto for this guide. Stopping a problem before it even becomes a problem is your best line of defense. Always check the pump before the start of a shift. Take it apart and check for wear and impact fusion, and never, ever clean the inside of a pump with any kind of metal cleaning scour. It will do more harm than good, creating little gouges inside the pump that will be a ripe starting point for impact fusion to form. A wooden popsicle stick is actually a good alternative for metal brushes.

It may seem like a waste of time to check the pumps every day, but it really is a great investment of your time! Overall, checking the guns, pumps, and hoses will not take that long, and it is better to find an issue before the fact than after.

And two, if you have an issue with moisture and the powder starts to ball up inside the fluidizing hopper, and gets into the pickup tubes, it will start to congest the powder flow. Powder should always be free flowing and fluidizing properly in the hopper. If it isn’t, a whole mess of issues will crop up. Smaller particles may even flow up and start creating impact fusion in the pumps. Take our advice above with regards to controlling moisture and humidity, and you’ll be alright.

To recap, we have gone over two the most important parts of job shop equipment: hoses and pumps. There are a number of ways that jobs can go wrong that involve these two parts, but a proper, daily maintenance schedule and some attention to detail will solve most of the said problems. Take care of your equipment, and it will take care of you.

Fiona Levin-Smith is Vice president of Marketing and Specification for IFS Coatings. For further questions or inquiries, visit www.ifscoatings.com