TechTalk: Chandler Mancuso, MacDermid Envio, on PFAS

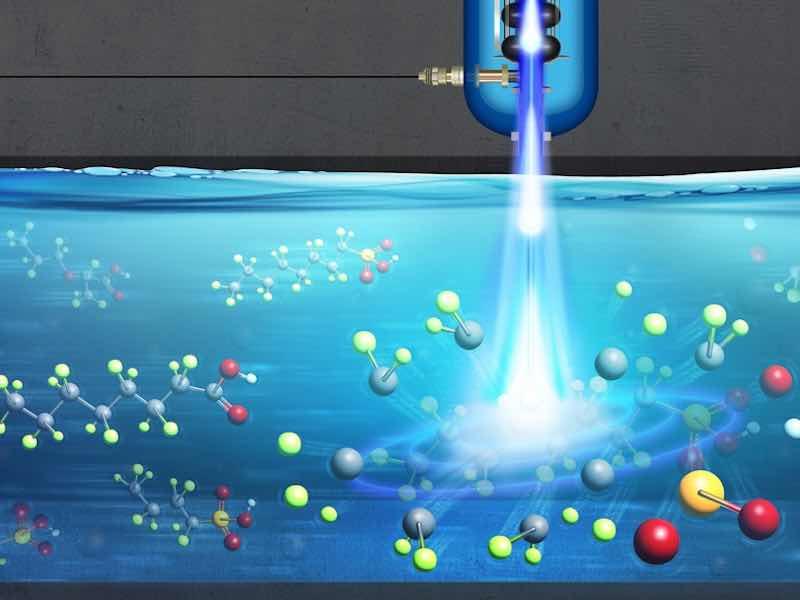

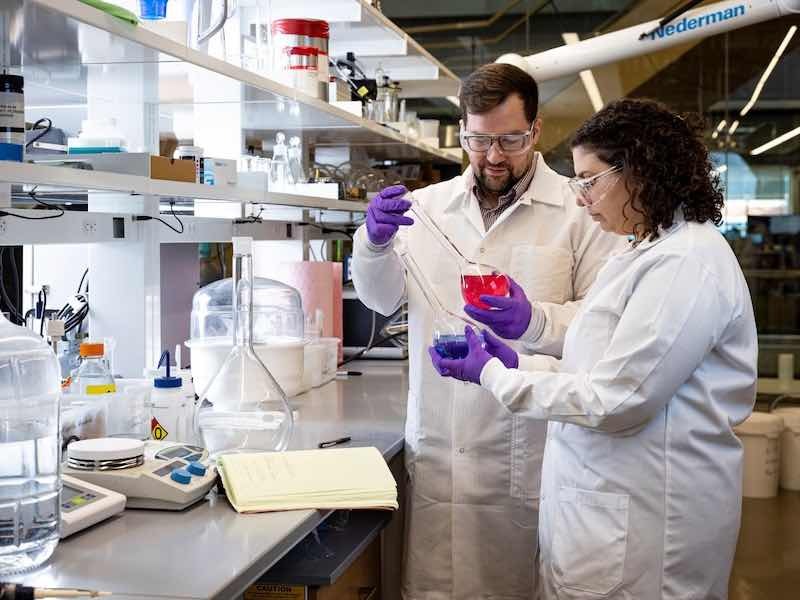

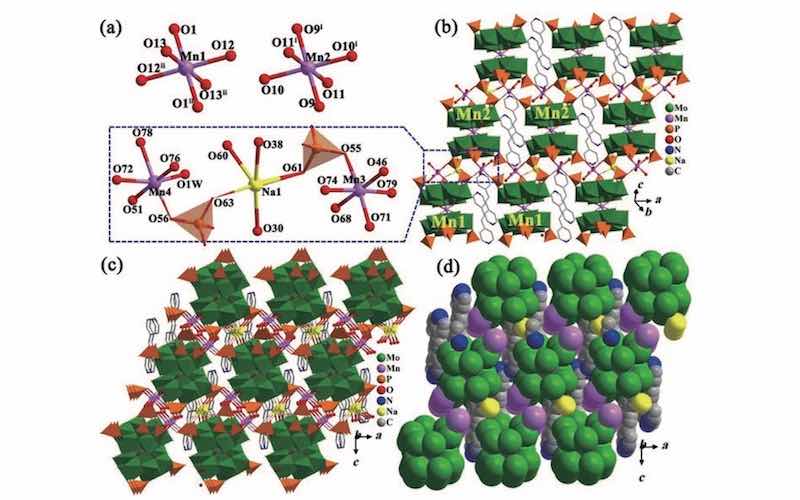

The issue of PFAS is top-of-mind for many in the finishing industry, and we spoke with Chandler Mancuso, Global Technical Director at MacDermid Envio Solutions, about what facility owners need to know.