The purpose of the salt spray test is to validate the “health” of an anodize process line.

W. John FullenThis test requires two weeks, which makes effective corrective action decisions paramount to avoiding long periods of downtime. By assimilation of many decades of Boeing documentation, external literature and consultation, an Anodize Troubleshooting Guide (ATG) has been developed. The ATG is a simple checklist and is mostly categorized by process solution but also includes sections on other non tankline processes, equipment, and salt spray test conditions.

W. John FullenThis test requires two weeks, which makes effective corrective action decisions paramount to avoiding long periods of downtime. By assimilation of many decades of Boeing documentation, external literature and consultation, an Anodize Troubleshooting Guide (ATG) has been developed. The ATG is a simple checklist and is mostly categorized by process solution but also includes sections on other non tankline processes, equipment, and salt spray test conditions.

Although this guide is specific to Boric Acid - Sulfuric Acid Anodizing many references can be applied to a broader application that can help guide process engineers to a quick and effective remedy.

Download the PDF of Boeing's guide HERE

Introduction

The basic salt spray (SS) test is relatively simple and dates back to 1914.

Shortly after the aluminum smelting process made aluminum a viable commercial metal1, the SS test was standardized by the U.S. National Bureau of Standards (NBS, now known as the National Institute of Standards and Technology, NIST). The neutral SS procedure was formalized as an ASTM B117 specification in 19392 with the currently used 5% salt solution becoming the industry standard in 195446.

Ever since the SS test first existed, failing results have needed to be analyzed. What makes this an insidious problem is that the causes of SS failure on anodized aluminum structure are numerous and, in many instances, not well understood. This article describes a systematic means for determining relatively quick root cause identification and describes the Anodize Troubleshooting Guide (ATG) that can be used as a process analysis checklist.

At Boeing, salt spray (SS) failure of anodized aluminum structure is a quality assurance (QA) test that determines the “health” of process line chemical solutions. Repeated SS failures will cause the anodize process solution to be “tagged.” QA then renders the process as “unavailable” for further processing, until corrective action and passing SS results have been obtained.

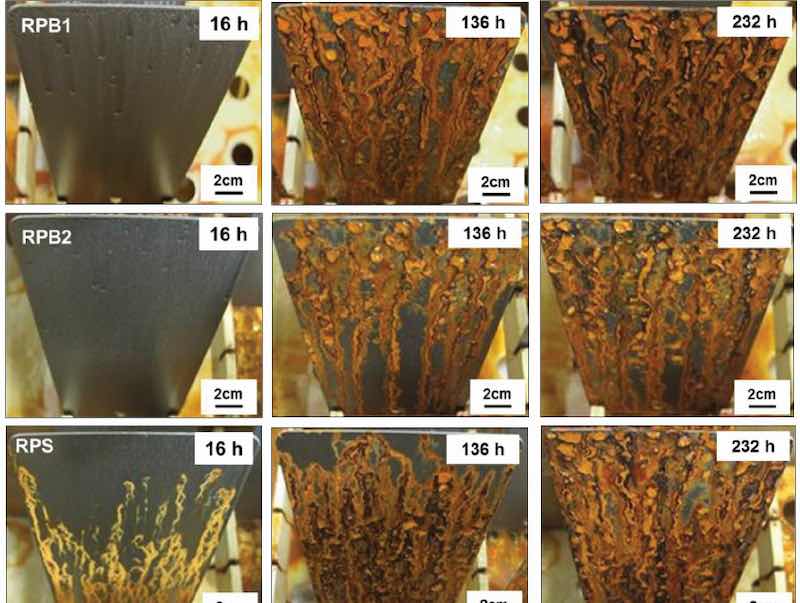

Test method ASTM B117 dictates that the test panels shall be kept in (Figure 1) for 336 hours (two weeks).

Figure 1: Salt Fog Chamber

Figure 1: Salt Fog Chamber

This inherently long test time makes effective corrective action decisions paramount to avoiding long periods of downtime. By assimilation of many decades of Boeing documentation, external literature, and consultation, a troubleshooting guide was developed. It is a simple checklist, categorized mostly by process solution, but also includes sections on other non-tankline processes, equipment, and SS test conditions (see Appendix). Although this guide is specific to boric acid-sulfuric acid anodizing50–52, many references are generic and can be applied to a broader application that helps guide process engineers to quick and effective remedies for other anodizing processes.

Process Solution Chemistry

A typical BSAA process involves emulsion degrease, alkaline etch, desmut, anodize, and then dilute Cr seal that are interspersed by rinsing [typically double counter current rinse (DCCR)]. Each process has a set of chemistry and parameter controls. Review of quality assurance log books rarely reveals an unnoticed “out-of-specification” condition.

However, a drift to one side of a range can result in a set of conditions that may lead to SS failure even when all QA numbers are “good.” For instance, two studies3,42 reveal that the high end of the sulfuric acid concentration results in better SS results. In any case, review of the QA log books is an easy first step.

Additionally, non-specification controlled chemistries may also be important. An example would be the ratio of Cr+6 to Cr+3 in a chromated deoxidizer solution.

When a deoxidizer is relatively new, this ratio should be above 7:1 and a well-used Cr deoxidizer solution would have a ratio of 2:1.

Silicated degreaser chemistry is known to result in hard scale on auxiliary equipment and has been discouraged from use when also using a dilute chrome seal process12. However, Boeing currently uses silicated cleaners and has been able to minimize scale formation and excessive silicates in solution by maintaining the degreaser pH26,27.

Temperature

Anodize temperature is tightly controlled (80+/4°F). Higher anodize solution temperature yields higher coating weights3,44 and is reported45 to even provide a reduction in pits caused during outdoor exposure testing. It is also interesting to note that BSAA temperature was negatively correlated with allowable sodium chloride concentration3. Given these competing effects, the middle of the allowed range is typically the best place for a set-point for the BSAA solution.

A chromated hot de-ionized water seal temperature is also tightly controlled, and studies4,5,21 have recommended that the upper end of the BAC 5632 specification (195°F–200°F) be used to improve overall SS pitting performance but at the cost of potential paint adhesion loss20. This is the opposite of what happens with the chromic acid anodize (CAA) process44.

The temperatures of other process solutions are controlled for reasons of etch rate (TEA etch) or cleaning performance (aqueous degrease) that are not directly related to SS performance. However, dryers that are used after the seal process should not be too hot or, purportedly8, the hydration amount can be affected by unintended seal solution weeping.

Immersion Time

Deoxidizer immersion time needs to be long enough to remove alloying metal oxides (smut), but studies4 have determined that six minutes should not be exceeded. This leads to understanding that etch rates should be kept at the low end of the specification range16,22 to reduce the potential for preferential etching of alloyed aluminum.

Anodize immersion times are crucial enough that this parameter is often automated or at least has a timer affixed with an alarm to signal the operator when the load must come out. Additionally, the load must be removed promptly when the rectifier has been shut off. This is crucial since the acid solution is removing anodize structure with every moment that the parts are being exposed to non-electrified anodize acid. If this parameter can be manipulated to be slightly longer, that would certainly produce higher coating weight5,42,44and, thereby, should provide better SS resistance to a weakened process. But studies44 have shown that anodize time only weakly contributes to corrosion protection.

Additionally, longer anodize immersion times may be counterproductive to paint adhesion characteristics17. The follow-on anodize rinse should be relatively short to avoid potential lower hydration values4 for parts that are subsequently sealed.

Seal immersion time is specified (23–28 min.) but being at the highest end of the allowed time would provide a higher hydration level and, thus, better SS resistance4. However, longer seal immersion times again may be counterproductive to paint adhesion results36.

Congruent to understanding immersion times is the load transfer time. Part movements should be quick enough so that they remain wet while in between tanks8,9,10,16,37. This illustrates the need for a troubleshooter to spend time on the shop floor observing the process, taking notes, talking to operators, and not getting totally engulfed in data analysis and acquisition.

Contamination

This section is where the ATG has the most information. Certain metal and inorganic ionic species contamination is expected as a process solution ages. Some of these chemical species are important enough to have required monitoring and, thus, are listed in applicable process specifications. For example, BAC 5632 requires monitoring of Al, Cl, Cr, and Cu. These species are known to be interactive. It is well known that higher amounts of Al, in BSAA, decrease oxide formation efficiency and can contribute to poorer salt spray performance as a BSAA solution ages42,44.

However, higher amounts of Al in BSAA will also result in a greater tolerance for Cl and, thereby, help remediate chloride pitting3. Chloride contamination buildup is lessened by charging the anodize tank with de-ionized water12,18,19,44. A very early study34 determined that much lower (50 ppm) chloride contamination in anodize solutions can contribute to attack on the tank walls. The resulting iron contamination can be significant and may then lead to lower coating weights.

In a seal tank, the most important contaminant to monitor is the amount of silicates—which is required to be below 10 ppm. However, some documentation22,23,41,43 have recommended even lower silicate values. It has also been shown45 that the effect of seal water silica contamination is pH dependent, with the worse result being at lower pH values in the range of five to seven. In the ATG, many of the other values listed for the seal solution are from an AESF course6,45.

Also in the ATG, the value for Mg has a range since studies have indicated that traces of Mg can help increase the corrosion resistance of sealed anodic film6. Also, very small amounts of phosphates in seal tanks reportedly help reduce smut formation and, thereby, help initiate “sealing” of hot DI water. Given the large number of documented ionic contaminants that can affect a seal tank, a frequent dump schedule is recommended24, especially if production rates are high.

Another item worth noting is that Boeing studies7,28 have revealed that excessive drag-out of “TEA etch” (contains sodium sulfide) will render the deoxidizer to be less effective by causing lower coating weights and subsequent paint adhesion and SS failures.

Table 1. Contamination criteria extract from Anodizing Troubleshooting Guide

| Check | Seal | BSAA | Deoxiders | TEA etch |

| Al | 5.5 g/L max. | 17.2 g/L max. | 2.5 – 10.0 oz/gal | |

| Cl | 50 ppm max. | 0.1 g/L max. | ||

| Cr | 500 ppm max. | |||

| Cr+6 | 45 ppm max. | 4.5 – 13.5 g/L | ||

| Cu | 15 ppm max. | 237 ppm max. | 0.2 g/L max. | |

| Fe | 15 ppm max. | 50 ppm max. | ||

| Fl | 5 ppm max. | |||

| Mg | 100 – 150 ppm | |||

| Na | 200 ppm max. | |||

| NO3 | 100 ppm max. | |||

| pH | 3.1 – 3.8 | |||

| Phosphates | 3 - 15 ppm | |||

| Silicates | 10 ppm max. | |||

| SO4 | 100 ppm max. | 50 ppm max. | ||

| Sulfide | minimize | |||

| Zn | 15 ppm max. |

The values in bold type (Table I) are those required by Boeing process specifications8–10. Incoming water quality should also be monitored and be commensurate8 with drinking water standards established by the World Health Organization (International Water Standards for Drinking Water, 3rd Edition WHO, Geneva; 1971). Of specific note is that incoming rinsewater chloride and fluoride levels not exceed 25 ppm and 1.7 ppm, respectively.

Equipment

There are several equipment checks that can be performed when investigating SS failure. Anodize racks and bus bars (Figure 2) should be kept clean and relatively free of heavy oxides4,8, since poor contacts can cause low anodize coating weights4,11,12,38. Additionally, any noted red gelatinous film on the anodize tank wall may be attributable to copper impurities and can be removed by plating out onto 1100 series aluminum.

Figure 2: Anodize Bus Bars and Racks

Figure 2: Anodize Bus Bars and Racks

Anodize power requirements must be adhered to strictly8. Specifically, the voltage ramp up must be 1.5 V/min. minimum, and the processing voltage is to be maintained at 15+/-1 V. Too quick of a voltage ramp-up may result in arc mark burning, localized coating dissolution, or powdery coatings31. If the operating voltage is too low, the resulting lower current density might contribute to SS failure; again, due to low resulting coating weights44.

The BSAA process requires slightly more amperage per square foot than does the CAA process19. The higher the current density, the more important becomes the quality of the output current (ripple)25. Rectifier ripple can be defined32 as the percentage of AC current that is passed through a rectifier on the way to the process. Ripple can be seen on an oscilloscope as a peak-to-peak voltage measurement of the output signal. Excessive ripple can cause a loss in coating weight and also may affect the integrity of the anodize structure.

Although there is no ripple requirement for BSAA processing, monitoring should be periodically performed using an oscilloscope. The ripple should be maintained relatively low31,35 (five to seven percent) by use of a ripple filter. The ripple filter is either an inductor, series of capacitors, or both, and is commonly referred33 to as a “choke.”

To prevent “spotting,” corrective action would be to attach a zinc anode to the racks prior to sealing. Sparge air agitation of an anodize solution provides uniform solution chemistry and helps to avoid hot spots (burning). However, according to one industry consultant, too much air agitation can contribute to SS failure. Also, slow cranes might allow parts to dry in between processes that would then contribute to low coating weights.

If converting to a BSAA process, seal tanks should avoid the use of fiberglass construction22 and anodize tanks should have the steam pipes constructed of Carpenter 20 instead of 316L stainless steel29.

Testing

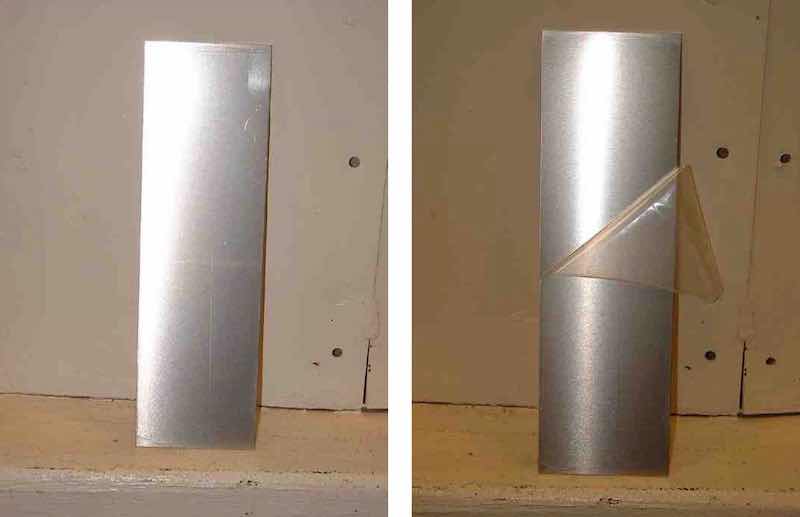

Figure 3: Salt Spray Test Panels (Mylar On and Off)An understatement is that the SS test is not known for being infallible15,30,39,40,45. A thorough investigator should determine (visually) whether the test panels are in good condition and should avoid the use of panels that have been in storage for an excessive period. Of course, the storage conditions will establish more exact storage times. To lengthen storage life, the SS panels can be kept in a cabinet and (ideally) be wrapped in Mylar (Figure 3). SS failure investigations have been previously traced to the condition of the test panels where, under magnification, defects have been visible on the panel surface13.

Figure 3: Salt Spray Test Panels (Mylar On and Off)An understatement is that the SS test is not known for being infallible15,30,39,40,45. A thorough investigator should determine (visually) whether the test panels are in good condition and should avoid the use of panels that have been in storage for an excessive period. Of course, the storage conditions will establish more exact storage times. To lengthen storage life, the SS panels can be kept in a cabinet and (ideally) be wrapped in Mylar (Figure 3). SS failure investigations have been previously traced to the condition of the test panels where, under magnification, defects have been visible on the panel surface13.

Additionally, incomplete removal of roll code ink markings from SS test panels has been attributed41 to premature SS failures. The anodized test panels8 should be a light gray color, have no burn marks, be free of cracks and pits, and have no powder residue before placing these in the SS chamber. There are many auditable parameters for the proper operation of a salt fog chamber46,47. Of particular importance are: the position of panels to avoid splatter and drips onto test surfaces40,47; nozzle air pressure48; and most recently (at Boeing) even the type of supply water49. Additionally, the investigator should inspect the interior of an SS chamber for areas of rust that might then be contributing to failures15.

When measured, the BSAA coating weight should be a minimum of 200 mg/ft.2 for 2024-T3 aluminum and 700 mg/ft.2 maximum for 7000 series aluminum. After seal, the hydration level should be 8%–14% as determined by Boeing test specification BSS 732514.

Summary

Anodize salt spray (SS) failures are infrequent due to the robust BSAA (Boric Acid—Sulfuric Acid Anodizing) process. However, when failures do occur, the problem is rather frustrating due to the numerous possible causes. The Anodize Troubleshooting Guide (ATG) is useful as a checklist to systematically isolate areas for further investigation. Boeing has used this technique on several occasions, and the result has been faster decisions for taking immediate corrective action and successful resolution of the anodize SS failure problem at hand.

W. John Fullen is with the Boeing Research and Technology (BR&T) organization, first in advanced composites but predominantly in chemical technology in support of tankline operations and the Boeing supply base. Prior to that, he worked at H.B. Fuller Co. in the area of adhesives. He holds a B.S. in Chemical Engineering from the University of Minnesota.

References

1. http://www.corrosion-club.com/historysaltspray.htm.

2. http://education.jlab.org/itselemental/ele013.html.

3. Boeing Operations Technology Development Report (OTDR) FF714S; 1995.

4. Boeing Manufacturing Development Report (MDR) 6-03146; 10/22/1986.

5. Boeing Operations Technology Development Report (OTDR) FF714A-1; 1993.

6. AESF Light Metals Finishing course; 1998.

7. Boeing memo, 6-3020-35-897; 1992.

8. Boeing Process Specification, BAC 5632, Boric Acid–Sulfuric Acid Anodizing.

9. Boeing Process Specification, BAC 5765, Cleaning and Deoxidizing Aluminum Alloys.

10. Boeing Process Specification, BAC 5786, Etch Cleaning of Aluminum Alloys.

11. Boeing memo, A-2020-11-315; 1985.

12. Boeing memo, 6-4620-40-91785; 1991.

13. Boeing memo, 6-4620-40-537; 1992.

14. BSS 7325, Gravimetric Method for Determining the Percent Hydration of Sealed Anodic Coatings.

15. Forshee, A.G., Metal Finishing, 89(10):45–47; 1991.

16. Boeing memo, 6-3020-11-1924; 1980.

17. Boeing memo, 6-4620-40-660; 1993.

18. Boeing memo, 6-4620-F1-98026; 1998.

19. Boeing memo, 6-4620-11-92961; 1992.

20. Boeing memo, A-2020-28-539; 1988.

21. Boeing memo, A-2020-24-597; 1987.

22. Boeing memo, 6-3020-11-1849; 1980.

23. Boeing Quality Control Development Report (QCDR), F168SO. 1978.

24. Boeing memo, 6-4620-42-3064; 1991

25. Pesic, S., Circuit World, 17(3):30–31; 1991.

26. Saunders, C., Evans, K., Sagers, N., Thiokol Corp.; Wash Solution Bath Life Extension for the Space Shuttle Rocket Motor Aqueous Cleaning System.

27. Boeing Manufacturing Development Report (MDR), A-99156; December 1999.

28. Boeing memo, 6-4620-42-4015; 1991.

29. Boeing Manufacturing Development Report (MDR), 6-03199; September, 1993

30. Brochure; Salt Spray–Facts and Fantasy, ONDEO-Nalco; (no date).

31. Boeing Manufacturing Development Report (MDR), 2-36495; 1988.

32. Henry, C., Plating and Surface Finishing, 91(3):26,; 2004.

33. Smith, C.C., Metal Finishing, 101(4):27–29; 2003.

34. Boeing Manufacturing Development Report (MDR), 6-03051; 1970.

35. Columbini, C., Aluminum Finishing, Oct/Nov:4–25; 1994.

36. Boeing Operations Technology Development Report (OTDR), 6-03207; 1993.

37. Boeing Process Specification, BAC 5763, Emulsion Cleaning and Aqueous Degreasing.

38. Boeing memo, 6-4620-11-91736; 1991.

39. Boeing Quality Control Development Report (QCDR), 252-811; 1975.

40. Boeing Quality Control Development Report (QCDR), 242-803; 1975.

41. Boeing Manufacturing Development Report (MDR), 2- 26816; 1970.

42. Boeing Development Document, D6-55313TN; 1990.

43. Boeing Manufacturing Development Report (MDR), 2-26817; 1970.

44. Boeing Operations Technology Development Report (OTDR), 6-03148; 1992.

45. Wernick, Pinner, & Sheasby, The Surface Treatment and Finishing of Aluminum and its Alloys, 5th Edition.

46. Frank, A., Plating, 47(6):623–631; 1960.

47. ASTM B117-03, Standard Practice for Operating Salt Spray (Fog) Apparatus.

48. Friedberg, H.R., Steel, 135(5):76; 1955.

49. ASTM D1193-99, Standard Specification for Reagent Water.

50. U.S. Patent 6,149,795; 11/21/2000.

51. U.S. Patent 4,894,127; 1/16/1990.

52. U.S. Patent 4,504,325; 3/12/1985.