Simon Haining is two years into his new job as president of High Tech Finishing in Houston, but one thing he has quickly learned is to listen to the customer.

President Simon Haining is leading a High Tech Finishing team that is adding an anodizing line, but also rebuilding from a major fire in May.The plating company specializing in aviation interiors is one of the most sought-after finishers for business jet owners, aircraft interior designers, and MRO facilities. But after a recent conversation with Gulfstream Aerospace, Haining knew he had to offer them more services.

President Simon Haining is leading a High Tech Finishing team that is adding an anodizing line, but also rebuilding from a major fire in May.The plating company specializing in aviation interiors is one of the most sought-after finishers for business jet owners, aircraft interior designers, and MRO facilities. But after a recent conversation with Gulfstream Aerospace, Haining knew he had to offer them more services.

“I’d been toying with the idea of installing some anodizing capability because it’s a good way to grow without having to grow in our existing market space,” he says.

The result is a new anodizing production line that High Tech commissioned in April that allows them to grow into an even more significant segment of the aviation industry.

Fire Delivers Major Setback

But just as High Tech was getting the anodizing line off the ground in May, a major disaster struck the business when an overnight electrical fire — traced to a heating element in a tank — disabled about 75% of the operations of the facility.

But Haining says High Tech’s employees did an amazing job in the first few weeks after the fire and got many of their lines back up and running.

“We are probably running at about 35% capacity right now,” he says. “It’s gonna take a couple of weeks to get back to normal.”

“I’ve got 126 people who are busting their ass trying to get everything back up and running and fixed.”

Haining says High Tech is working with two other nearby platers who agreed to let High Tech employees run parts during the night shift to keep their customers parts in production.

A major disaster struck the business when an overnight electrical fire disabled about 75% of the operations of the facility.“We’ve always had a very good turnaround time of a week or 10 days, where it seems the norm for the industry is two to three weeks,” Haining says. “So we are still able to get our customers their parts in plenty of time than they could get it anywhere else. We are still faster than most of our competition.”

A major disaster struck the business when an overnight electrical fire disabled about 75% of the operations of the facility.“We’ve always had a very good turnaround time of a week or 10 days, where it seems the norm for the industry is two to three weeks,” Haining says. “So we are still able to get our customers their parts in plenty of time than they could get it anywhere else. We are still faster than most of our competition.”

All the credit for the quick rebuild goes to the High Tech employees, Haining says.

“I’ve got 126 people who are busting their ass trying to get everything back up and running and fixed,” he says. “They have worked under difficult circumstances, and we haven’t had a single person quit. I think that’s pretty extraordinary, and it’s great to see something like that.”

Offering Four Anodized Colors

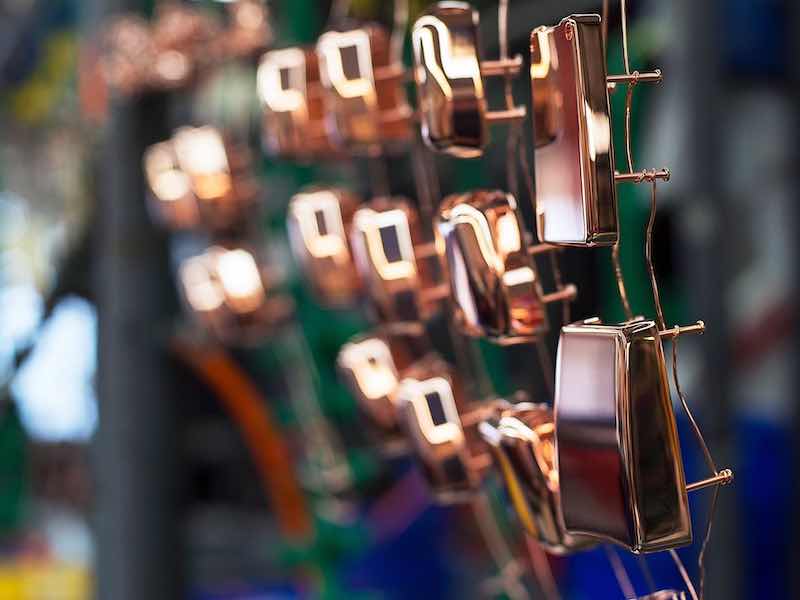

The new line will allow High Tech to offer four colors: clear polished, matte clear, black polished, and matte black.

The new line was something Haining — who was born in Scotland — has been contemplating since he assumed the presidency in early 2021 after serving as General Manager of a Precision Castparts Forged Products division of Wyman-Gordon, a worldwide aerospace & energy manufacturing company with offices in the U.K. and the U.S.

“The genesis of the idea came because we work with so many OEMs and refurb shops, and they would tell us, ‘this part going into plating, and this part’s going into anodizing,’” Haining says. “And over the last couple of years, I’m thinking, we really should be doing this because we have the expertise here. It’s different, but it’s similar enough that we really don’t need to reinvent the wheel to get it going.”

Over 130 Different Finishes

Before the anodizing line was christened, High Tech had booked work for one OEM and one refurbishment shop, and they hope to add to that growing list soon.

Before the anodizing line was christened, High Tech had booked work for one OEM and one refurbishment shop, and they hope to add to that growing list soon.

High Tech Finishing was founded in 1984 and provides over 130 finishes to a very picky clientele that is working to build or refurbish multi-million dollar jets and assorted aircraft. They earned their reputation by following a very strict, ISO-driven 50-step plating process to ensure the highest quality production, finish, and delivery for their clients’ aircraft interiors.

The owners of High Tech had originally purchased a small plating shop specializing in industrial work, tea sets, and miscellaneous hardware as an investment. A few years after opening their doors, they were approached about doing some work refurbishing a private jet, which piqued their interest. When they attended a trade show in the aviation section and realized they were one of only two plating shops to attend the event, they dug deeper and realized a market existed for specializing in aesthetic aerospace components inside the cabin.

“We learned quickly here that the secret to truly getting a good finish is in all the steps before a finish is actually applied,” says Rick Niefield, High Tech’s Vice President of Sales and Marketing. “With all the finishes we offer, it makes it that much more important to make sure that the base surface is prepared and ready to accept whatever finish has been selected. It’s a lot of work to get it right.”

Private Jet Business Continues to Grow

An analysis of the industry by Airbus Corporate Jets shows there in 2022, there were almost 15,000 private jets in the U.S., which happened to be almost 63% of the world’s entire fleet.

An analysis of the industry by Airbus Corporate Jets shows there in 2022, there were almost 15,000 private jets in the U.S., which happened to be almost 63% of the world’s entire fleet.

“The U.S. business aviation sector is the biggest in the world, and it is growing,” says Sean McGeough, Vice President of ACJ. “In the first six months of 2022, the number of business aviation departures in the U.S. was 15.2% higher than during the same period in 2019.”

Steve Deane with Stratos Jet Charters says that at the height of the pandemic, more travelers were looking to rent a private jet for health and safety reasons.

“However, as those first-time flyers discovered even more benefits to flying privately, they’ve since become loyal private flyers,” Deane says. “This demand has affected not just the number of private jets for sale, but also private jet statistics as a whole.”

For Haining, he had experience with plating and anodizing before coming to High Tech. He has a physics degree from the University of Strathclyde in Glasgow, Scotland, where he grew up. After supporting university research into quantum physics, he entered the aerospace and aviation environment to apply his understanding of metallurgy and metal properties in manufacturing settings.

Haining advanced from specializing in the technical side of manufacturing to becoming an operational leader, focused on refining processes that improve productivity and the quality of finished products.

“My experience with anodizing in my previous company was very industrial as we were anodizing pipes for oil and gas applications,” he says. “The customers didn’t really care what it looked like, so long as they had corrosion and wear resistance properties on the surface.

An Aesthetic Finish is Much More Important

High Tech Finishing was plating again just two weeks after the fire.But with metal components on a business jet, they’re not being abused the same way that an underground pipe is. For us, aesthetics is much more important.”

High Tech Finishing was plating again just two weeks after the fire.But with metal components on a business jet, they’re not being abused the same way that an underground pipe is. For us, aesthetics is much more important.”

Haining’s leadership has paid off handsomely, as sales have increased since he joined the company. And like most finishing operations, they are extremely busy, and the need to deliver quality products in the promised time is important.

Carl Bartuch Jr., CEO of High Tech Finishing, says they were impressed with Haining’s global business experience and deep understanding of manufacturing processes to optimize their delivery of finished parts to customers.

“Simon is the right person to lead our company forward, enhancing our lean manufacturing processes and building on our stellar reputation for high-quality decorative metal plating,” Bartuch says.

In analyzing where the sales increases have come from, Haining sales about 20% of the growth in sales has come from organic growth in the market. As aviation OEMs have seen the growth of their industry, High Tech Finishing has grown right with them.

“Gulfstream has increased, Embraer increased, and so on,” he says. “We picked up work organically from that, but the remaining 80% we had to go out and basically out-compete our competition. We had to go get the work by giving a better service, better on-time delivery, and better quality.”

Learning the Nuances of Anodized Finishes

High Tech is adding anodizing to increase the number of finishes it offers, which is currently over 130.Haining says that High Tech had run dozens of trials on its new anodizing line before it started full production for its customers, and they realized that anodizing has a few more nuances than plating does.

High Tech is adding anodizing to increase the number of finishes it offers, which is currently over 130.Haining says that High Tech had run dozens of trials on its new anodizing line before it started full production for its customers, and they realized that anodizing has a few more nuances than plating does.

“You don’t want a color mismatch from one corner to the next, and you also want to have consistency in time,” he says. “We also found there needs to be consistency in temperature and agitation; that has a huge effect on the overall look. There’s cleaning and polishing, for sure, but the temperature has a big impact on the finish, especially in the black color that we do. It really does vary if you don’t control the temperature really well.”

Luckily, High Tech had a great partner in MacDermid Enthone Industrial Solutions as both a supplier for its chemistry and also as a consultant and advisor on getting the anodizing line running smoothly.

Lance Mattfeld, a Technical Service Representative for the U.S. Western Region for MacDermid Enthone, says the company has not been as active in anodizing in the past, but with its acquisition of Coventya in late 2021, they now have the chemistry that meets many specifications required in aerospace, architecture, and automotive.

More importantly, MacDermid Enthone has added a dedicated Light Metals Solutions (LMS) group after acquiring Politeknik, which was based in Turkey and an industry leader in anodizing and other light metal finishes.

“Where we didn’t have all the approvals before, we’ve now changed gears, and in most cases, we’re pushing the anodizing to our customers because we have so many great products,” Mattfeld says. “It is a relatively small area for us now, but we certainly feel we can grow quite a bit.”

Since High Tech was already working with MacDermid Enthone on some of their plating chemistry, they went to them to ask if anodizing could be something they could easily integrate into their product line.

“We told them that we had everything they needed, and we can help you set it up for them,” Mattfeld says. “We helped them decide the physical setup they were going to need and showed them all the steps. And because they have such an excellent quality program, it really fell into place for them.”

Different Environment From Castings

Haining says he is enjoying his time with High Tech tremendously and that it is a much different environment than when he was with Precision Castparts, where the huge size of the global giant made it very difficult for things to be decided locally or decisions made quickly.

Haining says he is enjoying his time with High Tech tremendously and that it is a much different environment than when he was with Precision Castparts, where the huge size of the global giant made it very difficult for things to be decided locally or decisions made quickly.

As president of High Tech — which does about 35% of its work overseas — he is able to maneuver much quicker to respond to customer needs and to work on changes with his staff.

“At PCC, we had customers that can’t go anywhere else to get their parts but from PCC,” Haining says. “They’re supplying products that can’t be made any other way, so that really drives a lot of complacency in the business because they know the customer literally can’t go anywhere else.”

An Invigorating Change of Pace

High Tech has been a much different — and more invigorating change of pace — for Haining.

High Tech has been a much different — and more invigorating change of pace — for Haining.

“It’s very niche in what we do, as it’s very technical, and there’s some craftsmanship in the parts,” he says. “It’s actually not that difficult — we need some tanks, some solutions, and some rectifiers — and in theory, anybody can do this. So to keep us honest, we have to constantly be perfecting our processes, improving our training, hiring more people, and getting them up to speed with our quality system.”

That pursuit of excellence that Haining and his team enjoy at High Tech keeps him and his staff sharp on focused.

“Anything we can do to keep our noses in front of the competition, we need to continually strive to do that,” he says. “That is a factor that I didn’t really have in my previous company. It’s certainly tougher here because you’re not guaranteed your lunch. But for the team, this is pretty rewarding.”

Visit https://www.htf.net