Getting current efficiently to the anodizing tank is a must for all anodizing operations.

In the past, using lead cathodes from the tank wall or the lead cooling coils in the tank was a primary way to apply the current. As time went on, anodizing personnel found that lead was a very inefficient way to supply current in an anodizing operation (Table 1).

| Material Comparison | Relative Conductivity |

| Silver | 100 % |

| Copper | 58% |

| Gold | 44% |

| Aluminum | 36% |

| Carbon Steel | 5% |

| Lead | 4% |

| Titanium | 2% |

| Stainless Steel | 1% |

Eventually, anodizing companies agreed on aluminum to supply the current for the anodizing of their product, and after some research 6063T6 was found to be the most efficient and longer lasting alloy (Table 2).

| 6061T6 in 250 g/L sulfuric acid | 6063T6 in 250 g/L sulfuric acid | 6061T6 in 180 g/L sulfuric acid | 6063 T6 in 180 g/L sulfuric acid | |

| Weight loss after 7 days | 0.2891 grams | 0.4916 grams | 0.2355 grams | 0.4045 grams |

| % by weight lost after 7 days | 2.27% | 0.36% | 2.01% | 0.35% |

| Weight loss after 14 days | 0.6940 grams | 0.7579 grams | 0.5252 grams | 0.5288 grams |

| % by weight lost after 14 days | 5.57% | 0.55% | 4.59% | 0.46% |

| Weight loss after 21 days | 0.7798 grams | 0.7707 grams | 0.5994 grams | 0.4776 grams |

| % weight loss after 21 days | 6.63% | 0.56% | 5.49% | 0.41% |

| Weight loss after 28 days | 0.7480 grams | 0.7571 grams | 0.6039 grams | 0.6238 grams |

| % weight loss after 28 days | 6.81% | 0.56% | 5.85% | 0.54% |

| Weight loss after 35 days | 0.6461 grams | 0.7116 grams | 0.6270 grams | 0.5871 grams |

| % weight loss after 35 days | 6.31% | 0.53% | 6.45% | 0.51% |

| Weight loss after 42 days | 0.3908 grams | 0.3158 grams | 0.6129 grams | 0.5356 grams |

| % weight loss after 42 days | 4.07% | 0.24% | 6.73% | 0.47% |

| Weight loss after 49 days | 0.3893 grams | 0.2376 grams | 0.5488 grams | 0.5542 grams |

| % weight loss after 49 days | 4.23% | 0.18% | 6.47% | 0.49% |

In attachment of the cathodes, welding V/S bolting, old technology required anodizing companies to weld aluminum cathodes to what is generally known as a header-bar. For years this was accepted as the correct way to attach aluminum cathodes in an anodizing tank. The thought was that it sealed the connection between the cathode and the header-bar giving good electrical conductivity for the life of the cathode.

The disadvantage was when cathodes needed to be replaced, the system would need to be removed and the cathode cut out and replaced and rewelded. This could be a huge burden on an already stretched maintenance department or costly to have an outside contractor do the job.

Bolting had a bad reputation because of how it was done, not the least of which is the contact area of the cathode to the header-bar which is a very important component in a cathode system.

Bolting had a bad reputation because of how it was done, not the least of which is the contact area of the cathode to the header-bar which is a very important component in a cathode system.

Here are some of the facts about welding cathodes:

- Remember contact area is the important factor; when welding two plates of metal of any material the welded area, specifically the edge down to 1/4" - 1/2" is the only area which makes guaranteed contact.

- The areas beyond the weld, in the case of welding a plate of 4”x4”, will expand and bow outward, creating a void therefore stopping contact between the two surfaces that are welded.

- In addition, by welding, heat is built up in the aluminum changing the temper designation (T6) of the aluminum to an unknown or dead soft material. This can cause the aluminum to be susceptible to attack from the sulfuric acid in the bath.

- To eliminate this problem, use a good bolt pattern that assures good contact across the entire 4x4 surface.

- It is also important that once a year, the bolts are checked for tightness and if necessary, the cathode is removed, the area of contact is cleaned, and a light film of NO-OX (conductive sealant) is applied between the two aluminum surfaces just like when they are originally installed.

Finding and purchasing 6063T6 alloy aluminum does have its limitations as it is not a readily available material. It is a special extrusion with a unique treatment which is almost never kept in stock at aluminum suppliers in a usable profile.

Since most anodizing companies are not able to buy huge quantities and wait for delivery most settle for 6061T6 as a replacement material. The dilemma with 6061T6 is it dissolves at a much faster rate than 6063T6 (Table 2). This chart compares 6063T6 to 6061T6 in both low (180 G/L and 225 G/L) anodizing solutions.

As you can see, in the weight loss chart, the % weight loss on 6063T6 is much lower than 6061T6 in both 180 and 225 G/L based on the dissolution rate Table 2.

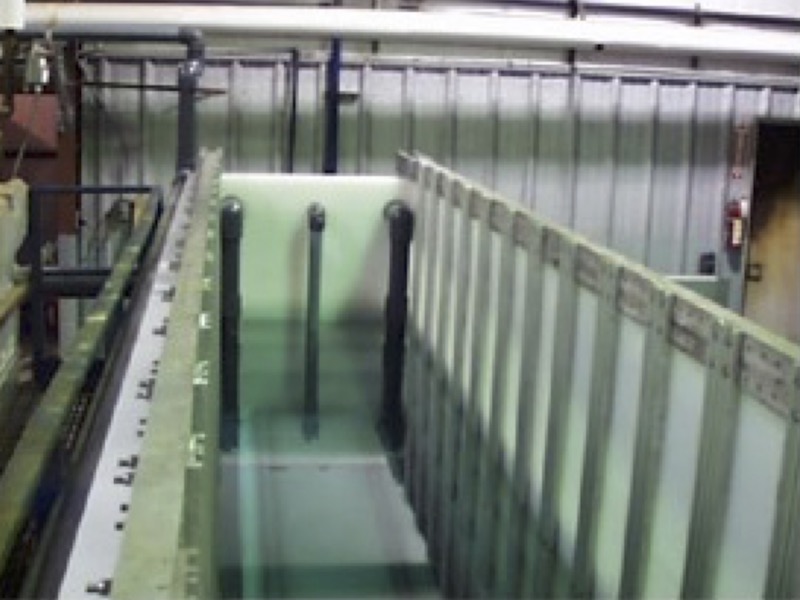

In practical terms you should expect 1-3 years of efficient service from a 6063T6 cathode setup like the system pictures above.

Drew Nosti CEF is President of Anodize USA; Joe Ciejka is a Research Chemist at Luster-On; Steve Guilbert MSF is retired from Luster-On. Visit www.anodizeusa.com and www.luster-on.com