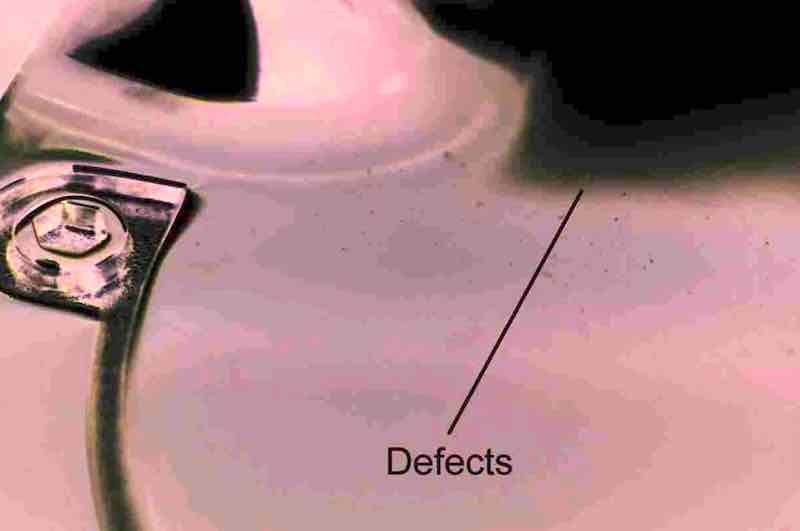

A shop reports observing minute defects in its decorative nickel-chromium-plated castings.

Frank Altmayer“They look like tiny blisters,” the shop manager told me. “The problem comes and goes, and right now it is coming at us pretty hard. Can you help us discover the nature and causes of this problem?”

Frank Altmayer“They look like tiny blisters,” the shop manager told me. “The problem comes and goes, and right now it is coming at us pretty hard. Can you help us discover the nature and causes of this problem?”

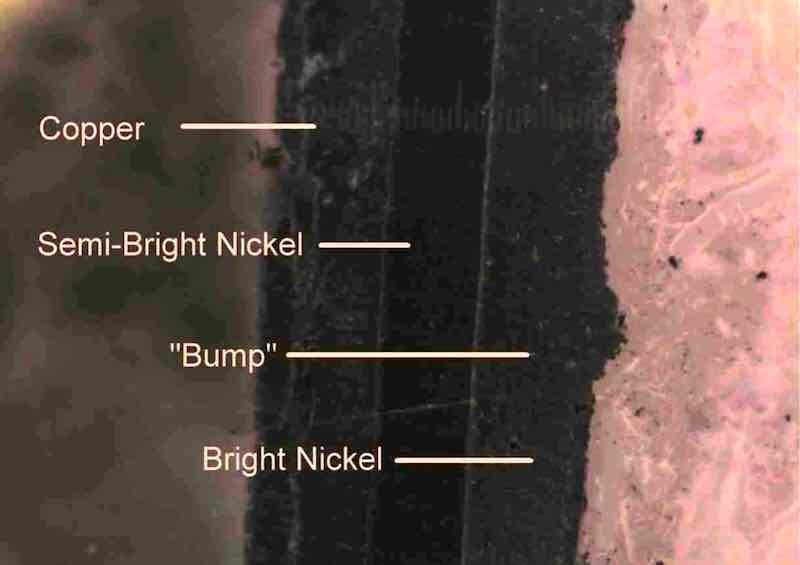

We cross-sectioned the defects (shown in photo 1) and examined them under the microscope. What appear to be tiny blisters are actually “bumpy” plating caused by trapped particulates. The cross-section showed that the bumps are in the bright nickel deposit, and we found several foreign particles within those bumps (photos 2, 3).

Culprit: Poor Filtration or Foreign Particles

The most likely cause is either poor filtration practice or the introduction of a continuous stream of foreign particles. One source of a continuous stream of foreign particles is your anode baskets.

Photo 1—Bumps in nickel deposit.

Photo 1—Bumps in nickel deposit.

Anode baskets must be bagged to prevent silt generated by nickel dissolution from entering the plating solution. If the top of the anode bags is below the liquid level in the plating tank, a clear path is created for particles to travel from inside the bag to the surface of your parts. As for filtration, it typically cannot keep up with the continuous stream of particles emitted by anode bags.

Photo 2—Cross-section of the deposit.

Photo 2—Cross-section of the deposit.

However, the following are good operating practices, as outlined in the AESF lesson on Filtration and Purification of Surface Finishing Solutions, co-authored by Jack Berg of Serfilco, Ltd., and me. In this lesson, Jack provides the following advice on filtration:

“Depending on the viscosity of the processing solution and the tendency of particulates to produce defects in those solutions, the required number of turnovers in a solution will vary,” Jack says.

‘Turnovers’ refers to the number of times per hour that the volume of the processing tank is processed through the filter. Turnovers dictate the size of the recirculation pump. In general, higher turnover rates yield higher filtration quality. The filter’s surface area determines how much solids can be retained before the flow drops too low, reducing removal efficiency (usually indicated by a pressure drop).

Nominal Porosity of the Filter

Photo 3—Cross-section showing trapped particle.The nominal porosity of the filter dictates the removal of 90–95% of all particles larger than that pore size. As a filter is used, the nominal pore size “automatically” is reduced by accumulated solids partially blocking the pores of the filter, so a filter that begins service with nominal 15 micron particle retention can quickly become a 10 micron filter in the presence of particulates.”

Photo 3—Cross-section showing trapped particle.The nominal porosity of the filter dictates the removal of 90–95% of all particles larger than that pore size. As a filter is used, the nominal pore size “automatically” is reduced by accumulated solids partially blocking the pores of the filter, so a filter that begins service with nominal 15 micron particle retention can quickly become a 10 micron filter in the presence of particulates.”

Solutions prone to generating large amounts of solids necessarily require higher micron ratings and larger filter surface area or solid-holding capacity.

For bright nickel, Jack recommends 4–5 turnovers, 7 ft2 of filtration area per 100 gallons of solution, and a 15–50 µm pore size (using cartridge filtration).

High flow rates through the filter are recommended, where possible and practical, to bring particulate matter to the filter quickly and thereby minimize or prevent particles from settling on parts being processed. No matter how fast the flow rate is, some degree of particulate contamination will always exist.

However, if continuous filtration is used at a relatively high flow rate, at about 4 to 5 turnovers per hour, and the filter is operated even during tank idle periods, a reliable particle removal rate will be successfully maintained. Typically, once four tank turnovers are employed, 97% of all filterable particulates are removed (assuming ideal mixing).

Goal: Higher Turnover Rate

The higher the turnover rate, the longer the plating tank can be operated without causing a significant increase in defective products. As the filtering system continues to operate, the flow rate declines and the pump pressure rises as the filter clogs due to particulate buildup. When this occurs, the filter must be serviced to restore the expected flow rate. From an operational standpoint, filter servicing should always occur before the pressure drop affects filtration quality. Frequent visual checks of the filter pressure or a visibly lower filter flow should be performed. If the solution appears cloudy or significant particulate is present, batch servicing of the solution should be considered (affecting production), or the filter service frequency should be increased.

Ideally, if the lowest particulate level is maintained in these solutions through proper procedures, optimal filtration can be achieved, and the need for batch treatment to remove excessive contamination can be minimized.

Failure to maintain the filter may require batch filtration of the process solution to ensure complete removal of particulate matter. This is accomplished by pumping the solution from one tank through a filter and then back into the process tank. Batch filtration is also recommended after a major change in the process chemistry.

Frank Altmayer is a Master Surface Finisher, an AESF Fellow, and the technical education director of the AESF Foundation and NASF. He owned Scientific Control Laboratories from 1986 to 2007 and has over 50 years of experience in the metal finishing industry. He received the AESF Past Presidents Award, the NAMF Award of Special Recognition, the AESF Leadership Award, the AESF Fellowship Award, the Chicago Branch AESF Geldzahler Service Award, and the NASF Award of Special Recognition.