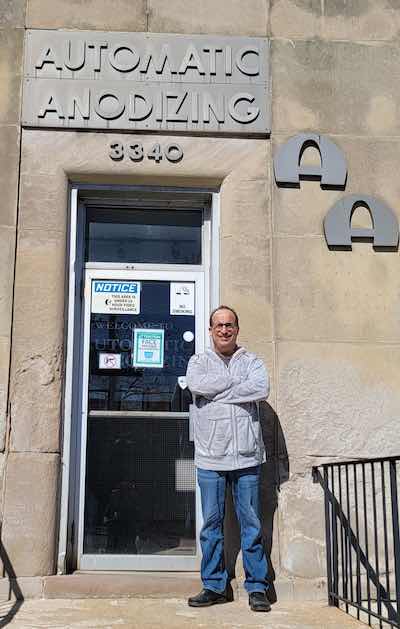

Business has probably never been better for owner Scott Penner’s Automatic Anodizing.

Scott PennerThe Chicagoland Anodizer and his team are busy every day applying three anodizing processes: Type II clear and back, Type III hard coating clear and black, and a chrome conversion that can be clear or yellow.

Scott PennerThe Chicagoland Anodizer and his team are busy every day applying three anodizing processes: Type II clear and back, Type III hard coating clear and black, and a chrome conversion that can be clear or yellow.

It seems he almost never has a spare moment to take a breath and catch up on things because of the bustling business coming in his door, so the question to be asked is: why is Penner fretting about what the future holds for his business?

“I just need help,” he says on the rare occasion he can take a few moments to reflect on his 76-year-old business that was founded in 1947. “I need some managers in here to get me to a second shift or even a third. We have that much work.”

The Search for Qualified Managers and Supervisors

Automatic Anodizing applies three processes: Type II clear and back, Type III hard coating clear and black, and a chrome conversion that can be clear or yellow.Like a lot of small businesses, Penner and Automatic Anodizing suffer from a dearth of skilled labor that wants to perform sometimes manual labor in a manufacturing environment. Finishers and coaters are especially feeling the labor pinch because of the type of work they do, which is often around hot tanks, lots of moving parts, and a workplace environment that some may not be conducive to today’s younger workforce.

Automatic Anodizing applies three processes: Type II clear and back, Type III hard coating clear and black, and a chrome conversion that can be clear or yellow.Like a lot of small businesses, Penner and Automatic Anodizing suffer from a dearth of skilled labor that wants to perform sometimes manual labor in a manufacturing environment. Finishers and coaters are especially feeling the labor pinch because of the type of work they do, which is often around hot tanks, lots of moving parts, and a workplace environment that some may not be conducive to today’s younger workforce.

All this plus the need to find workers who take pride in the quality of the end product. More importantly, Penner says he can’t find enough qualified managers that he can bring in to run a shift for him, so he can even explore the possibility of adding a second shift to take on the work that is available to his company.

“We have enough work for three shifts, and our business has been great,” Penner says. “I just don’t have the management to do it. The managers need some background in finishing, know how to manage people, and want to produce quality. It’s hard to find that combination.

“I’ve gone beyond my 10,000 hours doing this, but I don’t want to fool myself,” Penner says. “Just because you own a company, it doesn’t mean you know how to sell a company.

In fact, Penner says finding workers to fill a second or third shift is not a problem for him at the moment.

“General labor is not a problem,” he says. “We have good employees, and people know what their job is. I just need people who can actually be organized, and it’s so difficult to find those people for me.”

Too Many Open Jobs in the Market

Penner says he has been contemplating the idea of bringing in a partnership to help him run the company and plan for the additional shifts. Penner and others in the finishing and coating industry are not alone in not only growing their workforce but also finding the right managers to supervise and carry out stringent quality specifications.

Penner says he has been contemplating the idea of bringing in a partnership to help him run the company and plan for the additional shifts. Penner and others in the finishing and coating industry are not alone in not only growing their workforce but also finding the right managers to supervise and carry out stringent quality specifications.

A study in 2021 done by Deloitte and the Manufacturing Institute says that in the U.S., the manufacturing sector is looking to fill nearly 500,000 job openings. And they warn that the number is probably going to grow to over 2 million unfilled manufacturing jobs in 2030, a problem that could damage the U.S. economy by up to $1 trillion each year.

The Deloitte and MI study revealed that almost 1.4 million manufacturing jobs were lost during the pandemic, but more than 800,000 of those positions were filled once restrictions were lifted.

Penner says he has been searching for quite some time to find quality managers so he could add a second or even a third shift to his operations, which is housed in 20,000 square feet on Chicago’s northside.

The company was founded in 1947, and Penner’s father, Howard, purchased it in 1970. Penner has been with the company for over 26 years. They actively serve many industries, such as agriculture, aerospace, architecture, automotive, communications, electronics, fasteners, food services, medical, metal stampers, military, OEM, and tool and die.

Or, as Penner puts it: “Anyone who uses aluminum in their manufacturing process.”

Possibility of Bringing in a Partnership

Penner says he has been contemplating the idea of bringing in a partnership to help him run the company and plan for the additional shifts. He admits it can be overwhelming for an owner/operator to spend as much time as needed analyzing options and scouring the area for additional management help.

Penner says he has been contemplating the idea of bringing in a partnership to help him run the company and plan for the additional shifts. He admits it can be overwhelming for an owner/operator to spend as much time as needed analyzing options and scouring the area for additional management help.

“I’ve gone beyond my 10,000 hours doing this, but I don’t want to fool myself,” Penner says. “Just because you own a company, it doesn’t mean you know how to sell a company. That’s a totally different ballgame. I know anodizing, but I don’t know how to sell a business; that’s why I’m thinking of surrounding myself with people that do.”

Penner says getting beyond the 1.5 shifts he currently has operating will require some planning and coordination, and possibly a partner might help him — and Automatic Anodizing — get to that point.

But he wants to make one thing crystal clear: he is not interested in selling his business and going off into semi-retirement.

“I need someone that understands the importance of where we are in the supply chain,” Penner says. “More importantly, I don’t need someone to come in here and just fire all the employees, take our customer list, and be done. That’s not a solution for me.”

A Goal to Grow the Company

The company was founded in 1947, and Penner’s father, Howard, purchased it in 1970. Penner has been with the company for over 26 years. The goal for Automatic Anodizing and Penner would be for him to stay on and continue to help grow the company.

The company was founded in 1947, and Penner’s father, Howard, purchased it in 1970. Penner has been with the company for over 26 years. The goal for Automatic Anodizing and Penner would be for him to stay on and continue to help grow the company.

“We need to get into more markets and get into more customers,” he says. “With the boom of the internet and the marketing that goes with a good website — and being Google search friendly —I get customers from all over the Midwest and the rest of the country because most people today just Google searches for new vendors.”

About 15 years ago, Penner invested heavily into getting Automatic Anodizing ISO 9001:2015 certified, which he says has done wonders for the quality his operation now produces, despite the costs and the pain that it took to get there.

“ISO, in the beginning, was really scary, and it was a lot of money,” he says. “But what I’ve noticed now that we’re ISO certified going on 15 plus years is that it really cleaned up our process. It cleaned up our plant; it cleaned up our quality system. So now a new customer doesn’t necessarily have to come out here and visit us as long as they see that our ISO is up to date.”

Penner says he also doesn’t mind the ISO audits that go along with the certification.

“It cleans us, and it keeps us on our toes,” he says. “That’s the biggest difference, I think. At first, it was very scary, but in the end, I’m really happy that we are ISO and we maintain it.”

For the immediate future, Penner will work on looking for managers who could help him grow — especially managers and supervisors that have a finishing background and don’t require much hand-holding — and possible partners who can help take Automatic Anodizing to the next level.

“If we had managers, we could double or triple our workforce, and I think we could double or triple our sales,” Penner says. “I don’t have a single part order in my shop that’s guaranteed. We have no contracts, nothing. All we have is our reputation and our ability to communicate, and that’s how we keep our customers.”