Analysis of Multi-Component Dye Baths Using CIELAB, Reflectance Spectrophotometry

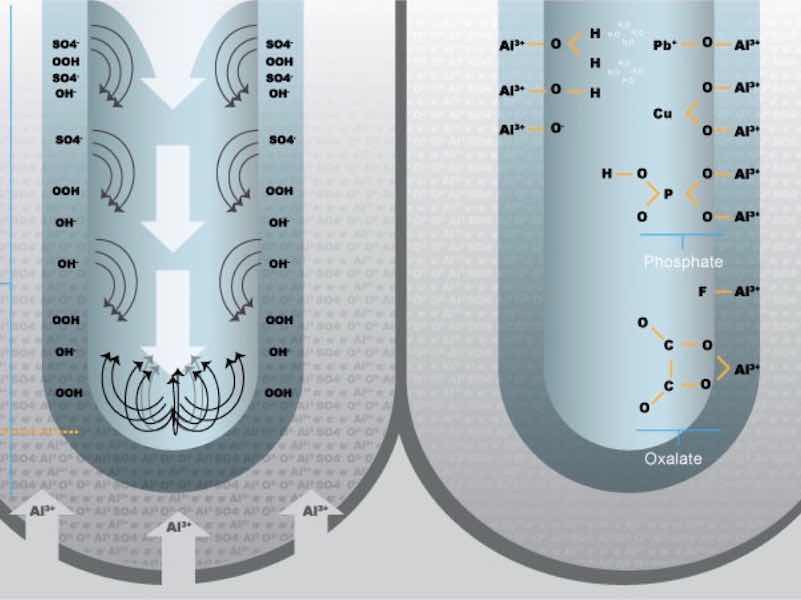

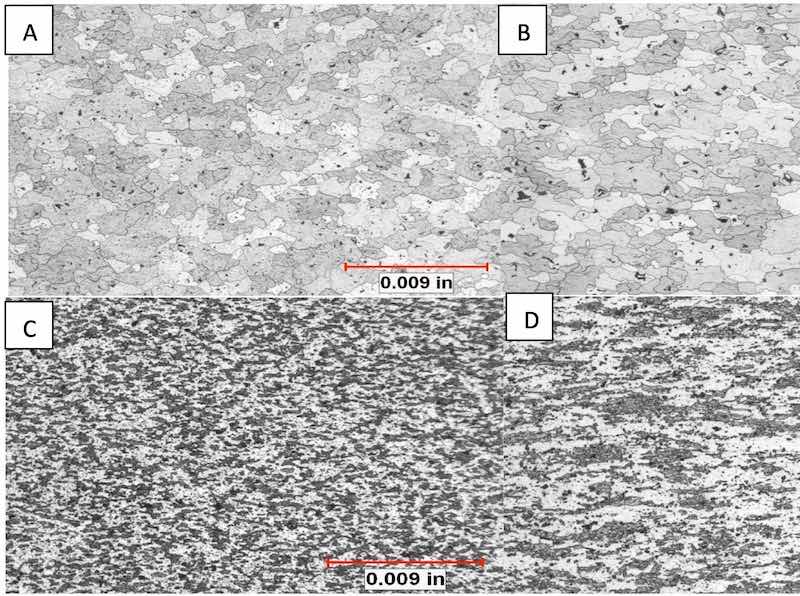

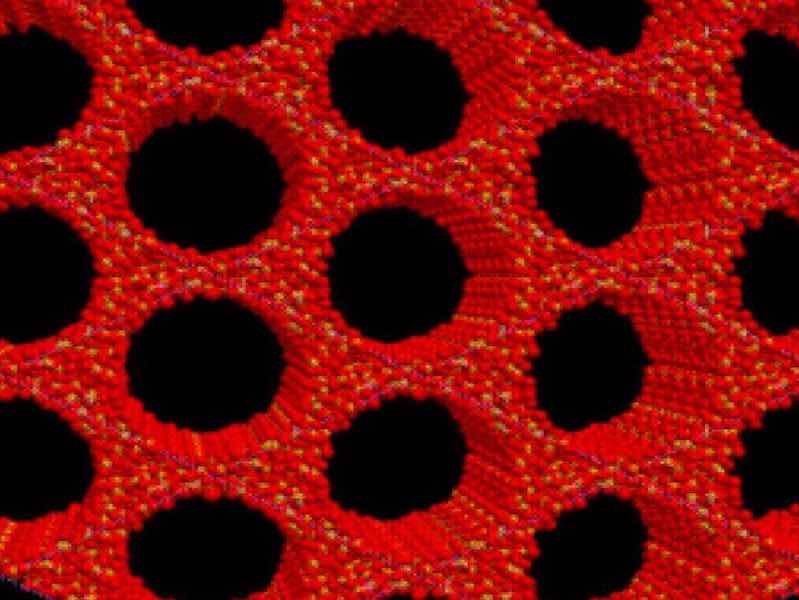

Using multi‐component dye baths in anodization processing can be a frustrating endeavor when not equipped with a basic understanding of color theory and how different dyes are affected by various factors.