Water is a limited, valuable resource. In manufacturing, using water strategically in critical cleaning can cut the costs of the cleaning process and of waste stream management.

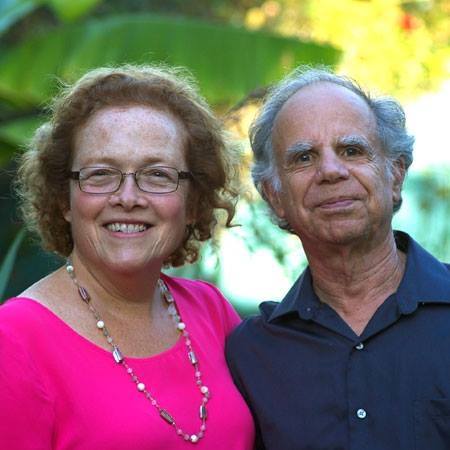

Barb and Ed KanegsbergUsing water correctly can result in a win/win – superior process performance and reduction of water use.

Barb and Ed KanegsbergUsing water correctly can result in a win/win – superior process performance and reduction of water use.

Aqueous cleaning is highly effective for many general, precision, and critical product cleaning applications. However, manufacturing uses a great deal of water. For example, one group estimates that it takes ~14000 – 22000 gallons of water to produce a car and ~3,200 gallons of water to make a smart phone (1,2); the amount of water used specifically for cleaning was not provided.

Usually, water for product cleaning must be of excellent quality; putting water back into a cleaning process that was used to mop the floor, or even to prepare salads in the company lunchroom, is not a reasonable plan. For many applications deionized or RO water is a must. In nearly all instances, you cannot use poor quality water in aqueous cleaning.

Environmental stewardship, sustainability, and being water-wise are important goals. Achieving those goals must include being able to stay in business and thrive. Here are few ideas for using water strategically.

Specific strategies are situational. To make it cost-effective for you as a manufacturer to reduce water usage, there must be a confluence of several factors. The product cannot be compromised. This means that water-wise cleaning performance must be equivalent to or, preferably, it must be better. Costs, including process costs (equipment, chemicals, monitoring, chemical management) need to make sense. Making sense includes initial investment, ROI, and ongoing costs.

Energy can be a significant cost factor. While it does cost money to heat water during washing and rinsing and to evaporate water during drying, these costs can be minimized by equipment design and facilities consideration. Involve facilities experts in factoring energy costs.

Water evaporates

For critical and precision cleaning processes, the cleaning agent (which is typically 90% water or higher) and the rinse tanks are heated. While temperatures can sometimes be decreased, heat is an important factor for effective cleaning. All other things being equal, there will be more surface area, and therefore more evaporation of water, with a spray process than with an immersion process. Because solvents tend to be more volatile and more regulated than water-based cleaners, aqueous cleaning processes may be conducted in uncovered tanks or spray areas.

Where possible, consider covers and enclosures. We sometimes see cleaning process tanks without covers, or instances where the covers are ignored. Debris from other processes and extraneous dust and insects does not contribute to effective cleaning; and ineffective cleaning processes tend to be more water-intensive.

Covers for cleaning equipment add to the initial capital investment, but covers can be money well-spent. In addition to minimizing unexpected contamination, containing the cleaning agent can be more pleasant and safer for workers (even aqueous cleaners have chemicals!). With less evaporation, there can be less of a strain on the HVAC system.

Rinsing

Saving water during rinsing can make good economic sense, but that does not mean to reduce rinsing. Multiple small rinses are more effective than a single large rinse (3).

With multiple rinse tanks, counter-flow or reverse cascade, where clean water at the final rinse tank moves upstream, can also be helpful. It can be cost-effective to design the equipment to minimize carryover of cleaning agent from the wash tank to the rinse tank. This minimizes loss of cleaning agent and keeps the rinse tank easier to manage.

Waste streams

What happens at the end of the cleaning process can cost a great deal of money. Those costs can be minimized and sometimes the rinse water can be recovered. Of course, manufacturers must comply with regulatory requirements. We often think about the costs of solvent disposal. However, there are costs associated with removing waste water and spent aqueous cleaning agent. On a practical level, non-compliance can result in fines or worse.

While some manufacturers can release the rinse water from the cleaning process to the POTW, in most instances, it is not allowed. Rinse water is likely to contain used cleaning agent, oils, dissolved metals, and metal fines. Some small manufacturers may find it financially favorable to avoid the equipment, monitoring, permitting, and inspection issues and have the water legally removed and disposed of by a third party (we think of that as “gift wrap the garbage and haul it off”). In other instances, usually larger applications, the rinse water can be cleaned and then released to the POTW or even repurified to the extent that it can be again used in the rinse cycle.

Communication

California has had a reputation for regulations, including those impacting solvents and aqueous waste streams. In many cases, the after-process water has higher cleanliness standards than the water coming into the facility. However, regulations are by no means restricted to California; and they are increasing throughout the U.S.

We agree with the assessment by Professor Darren Williams, leader of the Research Cleaning Group at Sam Houston State University, that critical cleaning processes would become better and more cost-effective if the people involved with waste stream management would communicate and coordinate with those involved in putting together the cleaning process. By doing so, manufacturers would avoid unnecessary last-minute “tacked on” equipment and costs. In the case of aqueous processes, we could also save water.

We hope you’ve found food for thought and may consider the benefits to manufacturing and to the earth in considering how to minimize loss of water. The concept is desirable; the specifics of achieving these objectives is situation-dependent. Success requires process understanding and looking dispassionately at the costs and benefits. In future articles, we will take a deeper dive into specifics of more efficient aqueous cleaning processes.

Barbara and Ed Kanegsberg founded BFK Solutions in 1994 as a critical cleaning consulting service and the go-to resource to make cleaning, surface quality, and contamination problems go away, or — even better — to avoid problems in the first place. Barbara, widely known as “The Cleaning Lady,” is an expert and trusted adviser in critical cleaning. Ed is known as “The Rocket Scientist,” and they write Clean Source, an approximately monthly e-newsletter that provides practical ideas to improve cleaning, contamination control, and product quality. They are co-editors of and contributors to the acclaimed two-volume “Handbook for Critical Cleaning,” CRC/Taylor & Francis, 2011. Visit https://bfksolutions.com

References

“The Hidden Water in Everyday Products;” https://www.watercalculator.org/footprint/the-hidden-water-in-everyday-products/

M. Berger, et al., “Water Footprint of European Cars: Potential Impacts of Water Consumption along Automobile Life Cycles”, Environ. Sci. Technol. 2012, 46, 7, 4091–4099 https://pubs.acs.org/doi/abs/10.1021/es2040043

B. Kanegsberg and E. Kanegsberg, “Exponential Rinsing,” Clean Source, May/June 2017; https://bfksolutions.com/exponential-rinsing/