Chemeon Surface Technology presented a poster for 1,000+ attendees to view during the Department of Defense's (DoD) Energy and Environment Innovation Symposium, which concluded on December 1.

Joseph Sullivan and Alexander Westre from Chemeon Surface Technology joined with Charles White, Ph.D., from the Naval Surface Warfare Center Carderock for the technical poster presentation “Novel Wipe-on Surface Preparation Tool for Corrosion Repair Facilities and Maintenance Depots.”

The Department of Defense's Energy and Environment Innovation Symposium is the nation’s largest conference focusing on the DoD's priority environmental and energy issues. The symposium brings together researchers, technology developers, defense end-users, and regulatory communities to showcase cutting-edge ideas in environmental and energy technology.

This year’s symposium took place from November 28 through December 1 and offered a variety of technical sessions and short courses at the Crystal Gateway Marriott in Arlington, Virginia.

Surface Touch-Up for Military Platforms

Sullivan and Westre shared during the symposium, “ Surface touch-up is vital as military platforms are assembled, serviced, and repaired, which requires new tools and techniques to be developed.”

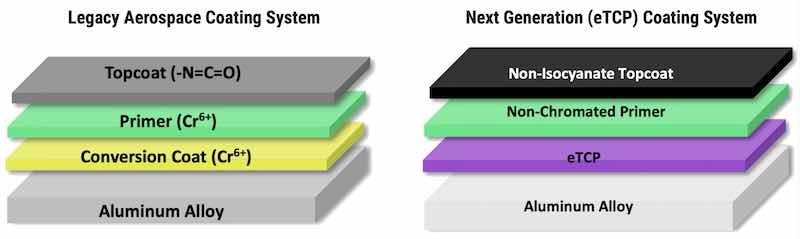

“For painted and bare aluminum, there is a need for a safe, easily applied conversion coating to prepare and protect the surface,” Westre says. “Current conversion coating / touch-up products on the market either contain hexavalent chromium or have poor performance. We created eTCP for immersion, spray, brush, and Touch-Up Pen to address this need. We have further developed this touch-up wipe-on tool, which provides excellent corrosion resistance and paint adhesion.”

“The wipe-on product was developed in conjunction with a Navy laboratory to better replicate use conditions for service assets and ground vehicles.”

The product utilizes the latest high-performance trivalent chromium conversion coatings, Chemeon’s patented eTCP. This next-gen conversion coating provides a visual color indicator that parts are coated and protected while providing superior corrosion protection and adhesion for aluminum alloys and other light metals. The eTCP technology arose from a SERDP/ESTCP-funded effort at the Fleet Readiness Center Southeast in collaboration with CHEMEON Surface Technologies 2016-2018.

“The current report discusses the implementation and performance of CHEMEON eTCP conversion coating as a wipe-on product,” Sullivan says. “The wipe-on product was developed in conjunction with a Navy laboratory to better replicate use conditions for service assets and ground vehicles.”

eTCP Developed as Readiness Enabler Technology for DoD

Chemeon President and COO Ted Ventresca says eTCP was originally developed in a powder and ready-to-use liquid form as a much-needed readiness enabler technology for the DoD. The performance of the safer, non-carcinogenic eTCP is approved for MIL-DTL 81706B and MIL-DTL 5541F.

“Our new eTCP wipe process and performance testing demonstrate its effectiveness for use at the base, depot, maintenance, repair, overhaul (MRO), and surface finishing level,” Ventresca says. “The improved surface preparation methods are described in the “Novel Wipe-On Surface Preparation Tool for Corrosion Repair“ poster that Sullivan, Westre, and Dr. White presented. The resulting coating is characterized by superior paint adhesion and improved corrosion resistance.”

The wipes were evaluated on multiple substrates, including steel, 2024-T3 aluminum, and 6061-T651 aluminum. Performance results are discussed by comparing different mechanical preparation techniques. Wiped unpainted panels were subjected to extended Neutral Salt Spray (NSS) to determine the corrosion resistance of the touch-up method.

This DoD energy and environmental Symposium is hosted by the environmental research and energy innovation programs under the Office of the Deputy Assistant Secretary of Defense for Environment & Energy Resilience (DASD E&ER). The Strategic Environmental Research and Development Program (SERDP) and the Environmental Security Technology Certification Program (ESTCP) fund research and demonstration projects, harnessing the latest science and technology to improve DoD’s environmental performance, reduce costs, and enhance and sustain mission capabilities. The Operational Energy Capability Improvement Fund (OECIF) and Operational Energy Prototyping Fund (OEPF) programs develop and prototype technologies that provide tactical overmatch for our warfighters and allies.

Visit www.chemeon.com and https://serdp-estcp.org