The price of gold has nearly doubled over the past two years, posing new economic challenges for the industry.

In times of such high precious metal prices, cost-saving solutions for material efficiency and process optimization are becoming increasingly important. Umicore Metal Deposition Solutions (MDS) offers proven processes for coating technical components with the hard gold electrolytes Auruna 526 and Auruna 527. These are technically and commercially impressive thanks to their excellent depth dispersion and uniform layer thickness distribution.

Umicore MDS has developed the weakly acidic gold-cobalt electrolyte Auruna 526 and the gold-nickel electrolyte Auruna 527, hard gold electrolytes specifically for mass coating of small parts in barrel plating and vibration coating systems. Despite the varying current-density conditions typical of these coating methods, these electrolytes enable a uniformly distributed gold layer of the desired thickness to be deposited on individual components. Conventional solutions often struggle to achieve uniform gold deposition on exposed areas and in recesses or cavities, especially in complex geometries such as plug contacts or contact sockets.

A very uniform layer distribution enables the minimum layer thickness to be achieved at specified measuring points without unnecessary use of gold – even in geometrically complex components such as pin, spring, and plug contacts, as well as contact sockets and sleeves.

A very uniform layer distribution enables the minimum layer thickness to be achieved at specified measuring points without unnecessary use of gold – even in geometrically complex components such as pin, spring, and plug contacts, as well as contact sockets and sleeves.

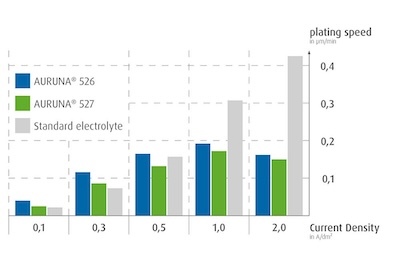

The two Auruna hard gold electrolytes ensure a balanced layer thickness ratio, resulting in a uniform minimum layer thickness across all relevant measurement points. This is based on the increased deposition rate at low current densities and the significantly reduced deposition rate at high current densities. This significantly reduces the overcoating typical of standard electrolytes and the associated unnecessary consumption of gold – an advantage that is particularly noticeable at internal measuring points of sleeves or sockets.

A comparison with a standard electrolyte shows a higher deposition rate at low current densities and a significantly lower reaction at high current densities. This results in more uniform layers in the application area of bulk material barrel/vibration coating – overcoating, and the so-called dog bone effect is significantly reduced.

As is customary with high-quality hard gold electrolytes, the layers deposited from them are abrasion-resistant and meet the highest requirements for corrosion protection and low contact resistance for reliable contact applications. In internal measurement series, the contact resistance is 3.33 mOhm for Auruna 526 and 3.26 mOhm for Auruna 527 (at 50 cN), which is characteristic of hard gold layers. The coated components can therefore also be used in demanding areas such as defense technology, as they comply with ASTM B488-01, Type I, Code C. This is due to a fineness of ~99.8% and a hardness of ~150 HV, which ensures reliable performance and durability.

"In these difficult economic times, our Auruna processes offer interested parties a simple way to optimize their cost structure and thus remain competitive," says Benjamin Wieser, Division Manager for Technical Applications Precious Metals at Umicore MDS, explaining the significant increase in demand for these hard gold electrolytes.

Another reason for the high demand is that both electrolytes impose no unusual requirements on the process landscape and can be quickly implemented on any plating line. They have a wide operating window, stable long-term behavior, and simple process control.