OML and IML anodize coatings often get damaged, especially around fasteners and leading edges.

Dr. Alan RoseFasteners eventually lose their Cd coatings and corrode, creating rivet rash. Since you cannot usually put the skin of an aircraft into an anodizing or plating tank, it would be really useful if you could repair the anodize and plating on the aircraft to return it to its original wear and corrosion resistance. Now you can do just that.

Dr. Alan RoseFasteners eventually lose their Cd coatings and corrode, creating rivet rash. Since you cannot usually put the skin of an aircraft into an anodizing or plating tank, it would be really useful if you could repair the anodize and plating on the aircraft to return it to its original wear and corrosion resistance. Now you can do just that.

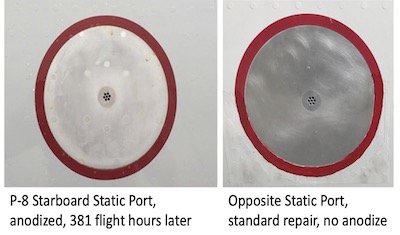

OML Anodizing

Replacing damaged or missing anodize on skins, floors, leading edges, and engine inlets is relatively straightforward with non-drip anodizing equipment. It does not matter whether the repair is on horizontal, vertical, or inverted surfaces.

It is even possible to replace the anodize on welded joints in aluminum cylinders such as aluminum tanks and first-stage spacecraft.

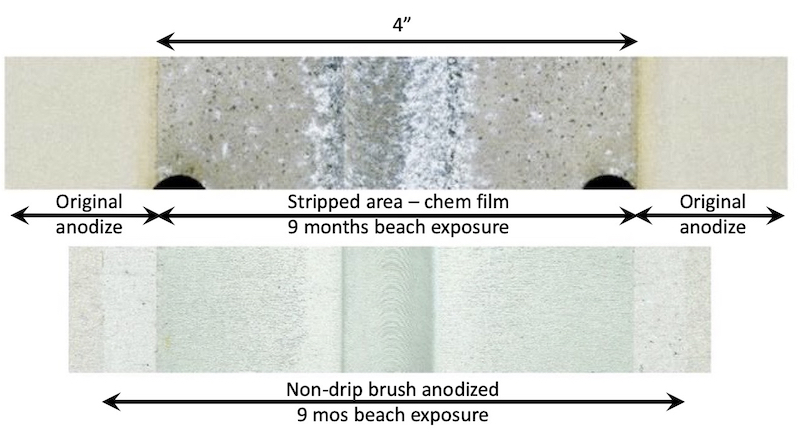

Large aluminum storage cylinders are usually manufactured in sections that are joined together by welding – often by the relatively new technology of friction stir welding. This requires stripping the protective anodize from the weld area.

Large aluminum storage cylinders are usually manufactured in sections that are joined together by welding – often by the relatively new technology of friction stir welding. This requires stripping the protective anodize from the weld area.

The weld areas are typically Chem-filmed since they are usually far too big to fit in an anodizing tank. Non-drip brush anodizing solves the problem, even on something as large as a space launch rocket.

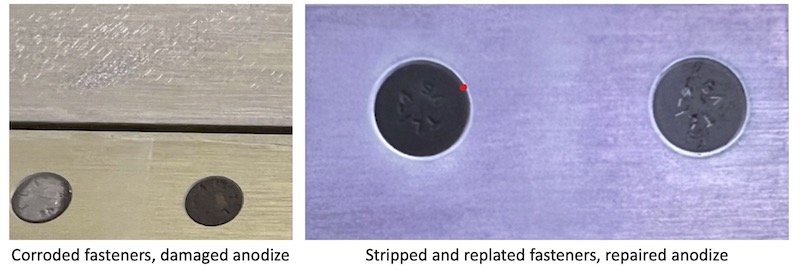

Replating Fasteners In-Place

Once the Cd plate on OML fasteners is damaged or lost, you are stuck with the problem of corrosion, poor paint adhesion, unsightly rivet rash, and ultimately corrosion damage to the surrounding aluminum skin. Until now, the only answer was to replace the fasteners – an expensive and risky proposition.

Now it is possible to electrochemically strip and re-plate all of the fastener heads and re-anodize all of the surrounding aluminum in place on the aircraft without having to strip and re-plate hundreds of individual fasteners, one at a time.

When dealing with this type of problem, one size does not fit all. Each problem is unique and often requires different tool designs and processes modified to fit the application.

When dealing with this type of problem, one size does not fit all. Each problem is unique and often requires different tool designs and processes modified to fit the application.

We prefer to use computational fluid dynamics and computational electrodynamics in all of our system designs. We model not just the tool but the entire problem – tool, fluid delivery, and return system, and the electrochemistry of the tool as it operates on the aircraft.

Most important of all, however, is that we use the new engineering discipline of Computational Corrosion Engineering to determine what coating should be used and how the repaired system will perform in service.

Dr. Alan Rose is CEO of Corrdesa, which develops and uses computer-aided engineering (CAE) simulation tools to identify and mitigate corrosion risk by optimizing and implementing corrosion-resistant coatings, processes, and equipment, ensuring compliance with regulatory and environmental requirements. Visit www.corrdesa.com