One might say that the pace of electrification in the automobile industry has gone into overdrive in the last year, and you would be right.

Timothy GotsickBut ‘gone into overdrive’ is not the best phrase to use because most BEVs (Battery Electric Vehicles) do not have a transmission, let alone an overdrive gear. Even so, the point stands: electric vehicles and their transitional form, the hybrid, are no longer a curiosity or a fringe market.

Timothy GotsickBut ‘gone into overdrive’ is not the best phrase to use because most BEVs (Battery Electric Vehicles) do not have a transmission, let alone an overdrive gear. Even so, the point stands: electric vehicles and their transitional form, the hybrid, are no longer a curiosity or a fringe market.

They are firmly in the mainstream for manufacturers and consumers alike. Their ascent is the biggest technological change in the automotive industry in our lifetime. Change of this magnitude brings risks and opportunities to an industry, and surface finishing will be no different.

Let’s explore some of the implications for automobiles, infrastructure, and the industry.

The Automotive Industry

Virtually all the established automakers have BEVs and hybrids for sale now. Disruptive technologies often come from outside the mainstream. Electric vehicles are a classic example. Although the idea of electric vehicles dates to the dawn of automotive technology, it took the outsiders at Tesla to push BEVs into the mainstream consciousness. A cottage industry documenting the vision and determination this took is already in place, and deservedly so. The entry of a new mark in the automotive world was unusual; the entry of an entirely new form of the automobile was one of the few events that truly deserved the term ‘disruptive.’

Virtually all the established automakers have BEVs and hybrids for sale now. Disruptive technologies often come from outside the mainstream. Electric vehicles are a classic example. Although the idea of electric vehicles dates to the dawn of automotive technology, it took the outsiders at Tesla to push BEVs into the mainstream consciousness. A cottage industry documenting the vision and determination this took is already in place, and deservedly so. The entry of a new mark in the automotive world was unusual; the entry of an entirely new form of the automobile was one of the few events that truly deserved the term ‘disruptive.’

Although existing automotive giants have rapidly closed the gap, this shakeup in the industry showed that new entrants could be successful. Tesla led the way, but BYD, Rivian, Polestar, Lucid, and NIO, along with many others, are now selling BEVs. Plus, virtually all the established automakers have BEVs and hybrids for sale now. The infusion of new thinking will accelerate innovation, but it will also challenge automotive suppliers for two reasons – the number of OEMs (and their specifications) to be served is greater, and the pace of technology development is higher than it has been in a generation. The new entrants and rapidly improving technologies will require close collaboration between surface finishing experts and EV engineers, many of whom may be interacting for the first time.

Automobile Technology

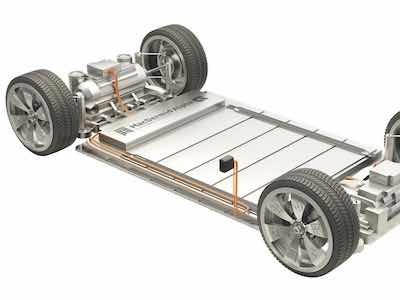

Electric motors can be mechanically simpler and lighter than an ICE, but the battery required to power it over an acceptable range will be much heavier.The changes in automobile construction will provide plenty of opportunities for surface finishing experts. Some subsystems in EV automobiles will not be much different than in standard ICE ones – steering, suspension, brakes, and passenger comfort and safety features will likely continue along their present development paths. However, the replacement of the ICE (Internal Combustion Engine), multi-speed transmission, and liquid fuel systems by single-gear electric motors fueled by electricity from batteries will have major implications for the materials used in their construction. For example, an electric motor can be mechanically simpler and lighter than an ICE, but the battery required to power it over an acceptable range will be much heavier and larger than an equivalent amount of gasoline or diesel liquid fuel. Let’s explore the implications of this change on components that are historically important to the surface finishing industry, as well as some entirely new areas that EVs will create.

Electric motors can be mechanically simpler and lighter than an ICE, but the battery required to power it over an acceptable range will be much heavier.The changes in automobile construction will provide plenty of opportunities for surface finishing experts. Some subsystems in EV automobiles will not be much different than in standard ICE ones – steering, suspension, brakes, and passenger comfort and safety features will likely continue along their present development paths. However, the replacement of the ICE (Internal Combustion Engine), multi-speed transmission, and liquid fuel systems by single-gear electric motors fueled by electricity from batteries will have major implications for the materials used in their construction. For example, an electric motor can be mechanically simpler and lighter than an ICE, but the battery required to power it over an acceptable range will be much heavier and larger than an equivalent amount of gasoline or diesel liquid fuel. Let’s explore the implications of this change on components that are historically important to the surface finishing industry, as well as some entirely new areas that EVs will create.

Fasteners

Electric motors have only rotating components and are far smoother in operation, so the average fastener size is likely to be reduced in the drivetrain of an EV.Nuts, bolts, and rivets are found throughout automobiles. They are central to the modern assembly line because they permit components from different sources to be joined efficiently and for those components to be repurposed over multiple vehicle designs. Fasteners make it easy to join dissimilar materials quickly and let the vehicle be serviced efficiently. Fasteners are sometimes regarded as a complication, but modern surface finishes have made fasteners durable, attractive, and safe even in demanding applications.

Electric motors have only rotating components and are far smoother in operation, so the average fastener size is likely to be reduced in the drivetrain of an EV.Nuts, bolts, and rivets are found throughout automobiles. They are central to the modern assembly line because they permit components from different sources to be joined efficiently and for those components to be repurposed over multiple vehicle designs. Fasteners make it easy to join dissimilar materials quickly and let the vehicle be serviced efficiently. Fasteners are sometimes regarded as a complication, but modern surface finishes have made fasteners durable, attractive, and safe even in demanding applications.

Fasteners will continue to be an important part of EVs as well. Although the demands on fasteners may change somewhat, the modern fastener plater will have many ways of meeting these new needs. ICEs have reciprocating components that experience incredible mechanical stresses in use, necessitating relatively large and high-strength fasteners in many cases (e.g., connecting rod bolts and main bearing caps). Electric motors have only rotating components and are far smoother in operation, so the average fastener size is likely to be reduced in the drivetrain of an EV. However, the need to join dissimilar metals, or metals with composite materials, will mean that the smaller fasteners used in their construction will need to have the highest resistance to corrosion.

Corrosion resistance is a strong point for our zinc-nickel plated finishes, which also can give clean, precision threads on these smaller fasteners. And many of those fasteners will benefit from the extra corrosion protection that passivates can bring (not to mention all the color options), while topcoats can be used to adjust friction characteristics and provide even more protection. Our surface finishing ‘toolbox’ for fasteners will give a lot of options for strong, beautiful, and clean fastening of new components in EVs as well as in all the existing automotive systems.

Decorative Trim

Some EVs have used less decorative chrome trim, but the full range of decorative plating options – recently extended by our paint on chrome process – will give a broad palette for vehicle designers to differentiate themselves.ICE vehicles have often used engine design as a point of differentiation, and many thrilled to the roar of a big block V-8, a tail of flame shooting out the wastegate of a turbocharged boxer 6, or the high-pitched rip of an inline four at 8,000 rpm. EVs may lack those sounds, but they are just as fast. And there is a good chance that our offspring will enjoy discussing rotor and stator upgrade options as much as we did carburetors and pistons. For both vehicle types, establishing brand equity through visual appeal is likely to remain a prime objective.

Some EVs have used less decorative chrome trim, but the full range of decorative plating options – recently extended by our paint on chrome process – will give a broad palette for vehicle designers to differentiate themselves.ICE vehicles have often used engine design as a point of differentiation, and many thrilled to the roar of a big block V-8, a tail of flame shooting out the wastegate of a turbocharged boxer 6, or the high-pitched rip of an inline four at 8,000 rpm. EVs may lack those sounds, but they are just as fast. And there is a good chance that our offspring will enjoy discussing rotor and stator upgrade options as much as we did carburetors and pistons. For both vehicle types, establishing brand equity through visual appeal is likely to remain a prime objective.

And although some EVs have used less decorative chrome trim, the full range of decorative plating options – recently extended by our paint on chrome process – will give a broad palette for vehicle designers to differentiate themselves.

Thermal Management

One of the inherent advantages of EVs is that they are highly efficient at converting stored energy to forward motion. This is because they do not produce as much waste heat as a combustion-based engine. But they are not 100% efficient and so some waste heat must be managed. The primary heat sources are the batteries themselves (during charging or discharging) and the inverters that convert the DC electricity stored in the batteries into the AC electricity that is used for most traction motors.

Managing the flow of heat, ensuring adhesion to other components, guarding against corrosion, and making electricity flow efficiently (or not at all in the case of insulating surfaces) are challenges that we expect to serve with our existing range of materials and new ones we will develop. We can add precision coatings of nickel, copper, silver, and many other elements to complex shapes in cost-effective manufacturing processes. This gives engineers the properties they need for high performance, longevity, and manufacturing efficiency in almost any application.

Weight Reduction

A keen understanding of how to optimize the preparation, cleaning, and surface finishing is needed to get the best results, and MEIS formed its Light Metals Solutions group for exactly this reason. Newtonian physics teach us that reducing mass is just as important as more power for improving acceleration. Reducing mass also helps address ‘range anxiety’ by letting an EV go further on a charged battery. This will drive automakers to increase the use of lightweight materials such as aluminum, reinforced plastics, and carbon fiber composites. Aluminum will be the first place to turn, as its strength/weight ratio, reasonable cost, and manufacturing flexibility are highly attractive.

A keen understanding of how to optimize the preparation, cleaning, and surface finishing is needed to get the best results, and MEIS formed its Light Metals Solutions group for exactly this reason. Newtonian physics teach us that reducing mass is just as important as more power for improving acceleration. Reducing mass also helps address ‘range anxiety’ by letting an EV go further on a charged battery. This will drive automakers to increase the use of lightweight materials such as aluminum, reinforced plastics, and carbon fiber composites. Aluminum will be the first place to turn, as its strength/weight ratio, reasonable cost, and manufacturing flexibility are highly attractive.

But aluminum is a complex material, typically used with various alloying elements to increase desirable properties. A keen understanding of how to optimize the preparation, cleaning, and surface finishing is needed to get the best results. We formed our Light Metals Solutions group for exactly this reason. This group has the expertise and products needed to protect aluminum, but also works together with our other surface finishing experts to make sure all the materials in a car stay strong, good-looking, and free of corrosion.

Electrification Infrastructure

Although perhaps not as photogenic as a new EV model on the floor of the Shanghai Auto Show, more EVs will mean lots of new chargers. Expect to see these popping up everywhere. The charging units themselves will be exposed to weather in many cases, but still need to look good, perform reliably, and prevent tampering. This is another area where our broad range of surface finishing technologies will play a big role. After all, no one will want to hook their EV up to a rusty charger! Both for the visible external components and the hidden internal ones, corrosion prevention, and electrical security will be critical needs as millions of new chargers are added to our cities, towns, and highways.

Another unappreciated benefit of EVs is that they become cleaner with time. This is due to the increasing use of clean energy production from solar and wind power. While our Offshore Solutions group works to make oil production cleaner and safer for the environment, our Industrial Solutions group is serving the heavy construction industry with strong, durable finishes that allow wind turbines to survive offshore and solar farms to operate continuously for decades.

Summary

The rise of EVs will make a serious dent in CO2 emissions in the long term. Drivers will also find a lot to like about them because they are quiet, fast, and comfortable. This change will disrupt one of our largest industries and open big opportunities. The good news is that MacDermid Enthone Industrial Solutions will be able to serve this new technology effectively today and is investing in new solutions to advance the performance, longevity, and beauty of EVs and their supporting infrastructure for the future.

Timothy Gotsick is Vice President of Technology and Innovation for MacDermid Enthone Industrial Solutions. Visit https://industrial.macdermidenthone.com