No one lamented the supply chain issues that U.S. manufacturers have endured over the past several years more than Gary Hamby, but he believes there is always an upside when things go down.

The President and Chief Executive Officer at H&M Plating in Houston, Texas, saw his company grow in volume when many oil and gas operators had trouble getting parts for their equipment and facilities.

Those supply chain problems forced many manufacturers to recondition their parts to keep operations going. Hamby and the four companies he runs — grinding, honing, and finishing — saw a huge benefit.

“With the supply chain issues, you had to fix parts because there wasn't anything to buy,” Hamby says. “I think that most of our people out there realize that they can get parts back faster — and can get it back cheaper — as a better product with the coatings we put on it.”

Aggressive Acquisitions Set Shop Up for Success

H&M Plating, Mirror Industries, and Schumacher-Dixie offer precision OD and ID pre-grind and finish grind processes to new or damaged cylindrical components and can polish parts up to 24 feet. Of course, Hamby and H&M Plating were in a perfect position to help those manufacturers thanks to an aggressive acquisition plan over the last decade that allowed them to acquire companies that augmented their finishing services.

H&M Plating, Mirror Industries, and Schumacher-Dixie offer precision OD and ID pre-grind and finish grind processes to new or damaged cylindrical components and can polish parts up to 24 feet. Of course, Hamby and H&M Plating were in a perfect position to help those manufacturers thanks to an aggressive acquisition plan over the last decade that allowed them to acquire companies that augmented their finishing services.

The acquisitions include:

- 2016’s Mirror Industries purchase gives H&M Plating about 40,000 sq. ft. for additional services such as electroplated hard chrome, thermal spray, OD/ID grinding and polishing, honing, welding overlay, phosphate coating, and media blasting.

- The purchase of all plating assets from R & M Energy Systems in 2016.

- 2019’s acquisition of both Schumacher Company and Dixie Electroplating, adding a combined additional 75,000 sq. ft. and a unit now named Schumacher-Dixie that offers hard chrome, sulfamate nickel, HVOF tungsten carbide, and pre-and post-polishing.

- 2021’s purchase of South Coast Grinding adds an even broader range of precision grinding capabilities in traditional ID, OD, and surface grinding.

All totaled — including the existing H&M Plating operations — the company has over 170 000 sq. ft. that can offer manufacturers electroplated hard industrial chrome, sulfamate nickel, HVOF, plasma coatings, electric wire arc thermal spray coatings, cylindrical grinding and honing, phosphate coatings, and media blasting services to industries spanning oil, petrochemical, marine, hydraulic, food, and manufacturing.

Plating is the Central Hub of Numerous Processes

Gary Hamby is President and Chief Executive Officer at H&M Plating in Houston, Texas.Hamby says having all of those facilities, employees, and services at their disposal made them extremely useful when manufacturers needed a host of services done to recondition parts and needed them back quickly.

Gary Hamby is President and Chief Executive Officer at H&M Plating in Houston, Texas.Hamby says having all of those facilities, employees, and services at their disposal made them extremely useful when manufacturers needed a host of services done to recondition parts and needed them back quickly.

The H&M Plating operations were the central hub of all of the other services with its coating operations.

“What they learned was that a lot of this new equipment is not coated, and they use it and wear it out,” Hamby says. “But after it's been coated, they realize they get more life out of it. I don't see that changing anytime soon.”

Hamby says that pre-pandemic, many of the customers they now have operated in a different mindset than they are today, while sustainability and refurbishing are key to their operations today.

“They are still sending us things you normally wouldn't see,” he says. “Five years ago, there were things that you just wouldn't see. They would throw them away and put another one in. But we're still seeing those things, and I think they're realizing that the coating industry is saving them money in the long run.”

Initial Focus Only On Chrome Plating

HM Plating offers hard chrome, thermal spray, OD/ID grinding and polishing, honing, welding overlay, phosphate coating, and media blasting.H&M Plating was started in 1971 and has now grown to a six-building complex of 65,000 sq. ft. It started as a chrome finishing operation; Hamby’s father also started Texas Honing, which was eventually sold to Warren Buffett’s Berkshire Hathaway group as part of the Precision Castparts Corp.

HM Plating offers hard chrome, thermal spray, OD/ID grinding and polishing, honing, welding overlay, phosphate coating, and media blasting.H&M Plating was started in 1971 and has now grown to a six-building complex of 65,000 sq. ft. It started as a chrome finishing operation; Hamby’s father also started Texas Honing, which was eventually sold to Warren Buffett’s Berkshire Hathaway group as part of the Precision Castparts Corp.

Hamby says H&M Plating only focused on chrome plating for many years until customers began asking them to handle other parts of the reconditioning process, including grinding and honing. They were outsourcing that work until they decided to perform the operations themselves.

“We were outsourcing our precision grinding to different shops, but the customers demanded deliveries that we couldn't make by outsourcing,” Hamby says. “Customers wanted quicker turnaround, so we started one machine at a time.”

One thing H&M Plating noticed right away was that they had far more control of the process than they realized; outsourcing the grinding caused them to extend coating times to perform another process, and that problem went away when they brought it in-house.

“We wanted more control,” Hamby says. “Before, if you had a problem and had to start over, it extended your coating times and costs because we all know the outside service guys never make mistakes. It's always the plater's fault.”

Learning Grinding Skills From the Ground Up

HM offers spot plating functions, as well.With his father's experience in honing to guide him, Hamby says he had H&M Plating start the grinding and honing process after hiring several craftsmen in the Houston area who were experts in the trade and learning it himself.

HM offers spot plating functions, as well.With his father's experience in honing to guide him, Hamby says he had H&M Plating start the grinding and honing process after hiring several craftsmen in the Houston area who were experts in the trade and learning it himself.

“We brought in good people, but my dad and I are very hands-on in the shop,” Hamby says. “I was out there and learned it from the ground up. I was as green as hiring somebody off the street when we started. But that's how we did it.”

H&M Plating learned quickly that being a one-stop shop for manufacturers was paying big dividends as the business began to grow, and they did a lot more non-plating-related work.

Soon, they began marketing H&M Plating more as a facility to get all the work done for reconditioning.

“Being a one-stop shop is our biggest selling point,” Hamby says. “We are so much better than our competitors that only do grinding or honing because if coatings need to be done, the vendors usually go to the coating shop to handle their parts. If you give a company not in the coating business a coated part, and they don't know how to treat it, it becomes a problem. We have a niche to be a one-stop shop for their grinding and coding needs, too.”

Normal turnaround time is three weeks for new parts and eight weeks for salvaged parts, but H&M Plating does offer a 24-hour turnaround upon request. It also operates multiple shifts 24 hours daily and seven days weekly to serve its customers better.

Expansion into Thermal Spray Coatings Grows Business

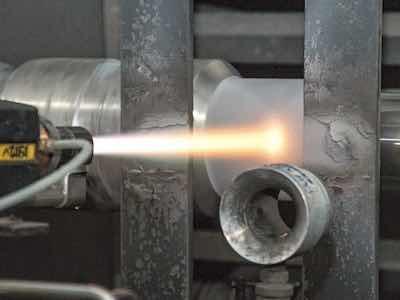

Hamby says that expansion into thermal spray coatings has been big for H&M Plating. High-velocity oxygen fuel (HVOF) coatings include Inconel and Hastelloy alloys, stainless steels, chromium carbides, and varying chemistries of tungsten carbide overlays. The tough and durable tungsten carbide coatings are available as sprayed or — if required — finished ground to specifications, which provides superior bond strengths, high density, and hardness properties to various machined components.

Hamby says that expansion into thermal spray coatings has been big for H&M Plating. High-velocity oxygen fuel (HVOF) coatings include Inconel and Hastelloy alloys, stainless steels, chromium carbides, and varying chemistries of tungsten carbide overlays. The tough and durable tungsten carbide coatings are available as sprayed or — if required — finished ground to specifications, which provides superior bond strengths, high density, and hardness properties to various machined components.

H&M Plating, Mirror Industries, and Schumacher-Dixie offer precision OD and ID pre-grind and finish grind processes to new or damaged cylindrical components and can polish parts up to 24 feet. In addition, among the 165 overall employees they have are certified on-site welders experienced in spot weld repair for damaged components and weld overlays.

“With us having our hands on it from start to finish, we know what to expect, and we know what we're looking for,” Hamby says. “We know what to protect and how to make it work.”

The Mirror Industries purchase was the first that Hamby initiated in 2016, a deal he had been looking at for quite some time. When he originally approached its owners, who were looking at retirement and selling the business, they balked when the economy picked up, and Mirror Industries became extremely busy.

“They didn't want to walk away from something that was doing well,” says Hamby, who returned to them a few years later when their business cooled off, and they were looking again at exiting the industry.

Access to 20-foot Chrome Plating Tanks

Greg Palma has been General Manager at H&M for over 20 years.The purchase gave H&M Plating access to 20-foot chrome plating tanks and several additional chrome plating tanks for use on various-sized parts. They had been limited in their length capacity previously. Still, the acquisition gave H&M Plating the ability to take on smaller parts in larger quantities and allowed them to begin doing chrome rotors and longer hydraulic and pump shafts.

Greg Palma has been General Manager at H&M for over 20 years.The purchase gave H&M Plating access to 20-foot chrome plating tanks and several additional chrome plating tanks for use on various-sized parts. They had been limited in their length capacity previously. Still, the acquisition gave H&M Plating the ability to take on smaller parts in larger quantities and allowed them to begin doing chrome rotors and longer hydraulic and pump shafts.

Purchasing the assets of R&M Energy Systems increased the depth capacity of its chrome plating department. They also installed additional chrome plating tanks with a capacity of 30 feet deep.

“Mirror could do some 20-foot parts, and they had two 20-foot tanks that we could start doing some of the bigger hydraulic work,” Hamby says. “One of our goals was to get into the hydraulic repair business. We wanted to move slightly away from oil and gas and diversify into something else. The 20-foot tank set us off in the hydraulic business, and it's taken off since then.”

The Schumacher-Dixie purchase came right before the pandemic occurred in 2019, and it allowed H&M Plating to consolidate many of the operations that were overlapping at the parent company and with Mirror Industries.

Schumacher was founded in 1941 and grew to be one of the larger finishing operations in the Houston area by offering hard chrome, grind, and electroless nickel coatings. They eventually started a subsidiary, Spraymetal, that offered metalizing, hard surfacing, heat treating, and ceramic coatings.

In 1981, Schumacher bought Dixie Electroplating to add capacity. By the 2000s, they opened a second Spraymetal location in the area. Also, they purchased two additional locations across the street from Schumacher's original location to perform chemical strip operations and tungsten carbide processing.

Expansion into Mud Rotor Business is a Boon

Jimmy Hairell has been in Sales, at H&M for 17 years.Schumacher also expanded into the mud rotor business, heavily used in oil and gas drilling operations. The mud rotors use drilling fluid pumped in to create motion in the section of the drilling system that moves the drilling bit. The expansion included more capacity for hard chrome, sulfamate nickel, HVOF tungsten carbide, and all of the pre-and post-polishing required to support these processes.

Jimmy Hairell has been in Sales, at H&M for 17 years.Schumacher also expanded into the mud rotor business, heavily used in oil and gas drilling operations. The mud rotors use drilling fluid pumped in to create motion in the section of the drilling system that moves the drilling bit. The expansion included more capacity for hard chrome, sulfamate nickel, HVOF tungsten carbide, and all of the pre-and post-polishing required to support these processes.

“Their plating capacity is just unbelievable compared to what I'm used to,” Hamby says.

When H&M Plating purchased Schumacher-Dixie, they also began consolidating the numerous coating processes they were offering.

“We got away from some of those coatings that they were doing, such as the spray metal, which didn’t have a market anymore,” Hamby says. “We phased out their HVOF department because we were doing it already and could absorb that work. We were after the chrome.”

Schumacher-Dixie has multiple 22-foot-long tanks and three plating buildings, something that H&M Plating very much wanted to acquire. The Mirror Industries facility was also moved into the Dixie facility and consolidated.

“That allows us to continue with our hydraulic work, which has been a big deal for us now that we can do the long stuff,” Hamby says.

Grinding Demand Leads to South Coast Acquisition

Supply chain problems forced many manufacturers to recondition their parts to keep operations going.The South Coast Grinding purchase in 2021 came about because grinding wasn’t a part of the other acquisitions, and the demand in that area was growing, too.

Supply chain problems forced many manufacturers to recondition their parts to keep operations going.The South Coast Grinding purchase in 2021 came about because grinding wasn’t a part of the other acquisitions, and the demand in that area was growing, too.

They were able to pick up almost 30 precision grinder stations and the personnel with the expertise to perform that type of work. They now have 15 employees devoted to nothing but grinding.

“We were tight on grinding, and there wasn't a lot of grinding that we bought in Mirror,” Hamby says. “Schumacher had several machines, but they were not maintained over the years. We needed capacity, and South Coast is a little shop just around the corner from H&M. I've known that gentleman for a long time, and he was ready to retire as well.”

Hamby is also about to look in the rearview mirror of his finishing career. Last May, he sold all the entities that makeup H&M Plating to Equity Launchpad, a Houston investment group led by managing partners Feras Moussa, Ben Suttles, and Casey Minshew.

But Hamby will be around for a while as he helps transition the company to new owners and allows his experienced managers of each operation to take on more responsibilities in running the company.

A Company of Skilled Managers

The company has over 170 000 sq. ft. that can offer manufacturers electroplated hard industrial chrome, sulfamate nickel, HVOF, plasma coatings, and other services.Before the expansion began in 2016, Hamby managed roughly 60 employees. He oversees almost triple that today and has just as much fun doing it.

The company has over 170 000 sq. ft. that can offer manufacturers electroplated hard industrial chrome, sulfamate nickel, HVOF, plasma coatings, and other services.Before the expansion began in 2016, Hamby managed roughly 60 employees. He oversees almost triple that today and has just as much fun doing it.

“It's been challenging for us, sure, but we've had good people,” Hamby says. “Our people have done a remarkable job. Many of my managers have been here for 15-plus years, and I don't micromanage very much. I hand them the reins and let them go.”

He says he enjoys the work after all these years and will miss the daily activities of running a finishing operation, grinding, and other processes. But he isn’t going anywhere too soon.

“I am here for a couple of years unless they run me off,” Hamby chuckles.

Visit www.hmplating.com