Before we get this train moving, we should probably define what exactly a special effect coating is.

Fiona Levin-SmithThe list is pretty long, as essentially everything that is not a solid color can fit into this category. The definition of a special effect can also differ between powder manufacturers and job shops. Some of you may consider low glosses and matte finishes as special effects; others may not. Most companies will say that metallics fall under the special effects class – however, we have a whole guide dedicated to metallics here and will not be focusing on them in this guide.

Fiona Levin-SmithThe list is pretty long, as essentially everything that is not a solid color can fit into this category. The definition of a special effect can also differ between powder manufacturers and job shops. Some of you may consider low glosses and matte finishes as special effects; others may not. Most companies will say that metallics fall under the special effects class – however, we have a whole guide dedicated to metallics here and will not be focusing on them in this guide.

We will cover why we use special effects, what their chemistry is, how to use them, how they can go wrong, and we’ll give you some top tips for how to use these particular coatings best. Specifically, we will cover wrinkles, translucents, dormants, river veins, multi-components, and fine textures.

Why Do We Use Special Effects?

Most of the time, what it comes down to is what your customer wants aesthetically. Perhaps they need a rusty-looking finish, a rough texture, or an extra something to make the part stand out from the crowd. It is usually driven by the customer needing a specific aesthetic or designers aiming for particular looks. However, the need for a special effect could also come from the need to hide a substrate surface that doesn’t look good. This is the main functional reason for using them.

What Can Affect a Coating Like This?

Typically, what kind of special effect you use is not affected by what the substrate itself is. However, pretreatment systems can affect how well a coating applies and cures. Galvanized, especially hot dip galvanized, the substrate can cause issues with outgassing – which we will talk more about in the next guide, Appearance Issues: When Jobs Go Wrong. A wrinkle effect can be botched by an improperly cleaned surface. Translucents need a clean, even substrate with a uniform appearance; otherwise, results in the final coat will vary.

Then there is the application process itself. Like with any coating, if it is not applied correctly, it will likely not cure properly, resulting in, if not an outright reject, an unattractive finish. Some powders will even change in color or pigmentation depending on how thick the film is.

Wrinkles

Most commonly, wrinkles are typically a polyester or urethane chemistry, occasionally an epoxy. Check out our blog on the different types of powder chemistries and the advantages of each to fully understand the best applications for urethane powders.

Most commonly, wrinkles are typically a polyester or urethane chemistry, occasionally an epoxy. Check out our blog on the different types of powder chemistries and the advantages of each to fully understand the best applications for urethane powders.

Now, wrinkles can be a tricky coating to get right. So as we always say, if you’re new to working with urethanes, this is probably a coating you want to test out on some sample panels before moving on to coat the part. So let’s break down where things can go wrong with this special effect. First up, the application and substrate! If your surface is not consistent in cleanliness and texture, the wrinkle effect will look different; some spots may work well, and others not so well – if at all. Secondly, the oven. If the temperature varies, say, by a few degrees in one corner, then you are going to get varied results in your finish. Check your oven settings and test out a few panels to ensure everything is in tip-top shape. Urethane wrinkles can also be sensitive to heavy film build on the edges – so be mindful of that when applying them. When wrinkles are done right, they look amazing. Get it wrong, though, and you have a doozy of a reject to deal with.

Why Use Wrinkles?

Wrinkles offer a very specific look. Smooth, classy, and sophisticated wrinkles are a comparatively mild special effect that can add real depth to the color and are pretty good at hiding the substrate. Not only are they a great visual effect, but they also have decent weathering, good hardness, corrosion resistance, and chemical resistance, and they are a great special effect for covering up surface imperfections.

In general, urethane-based coatings are good for chemical resistance. They are durable too. But, they do bring a lot of process issues with them. Like wrinkles themselves, if urethanes aren’t applied right, they go very, very wrong.

How Do I Apply Wrinkles?

The key to a good wrinkle is preparation. Have a good pretreatment system in place. No matter if you shot blast or use chemical pretreat, keep it consistent across the board. Clean all contaminants, especially oil, from the part and ensure the pretreat is applied evenly as any dirt or contaminants can interfere with how the wrinkles form.

Next, depending on whether you use a batch oven or an automatic system, you need to be sure that it is a conventional fire oven. You need to be able to ramp up the temperature quickly at the start of the cure cycle to ensure consistent wrinkling in the coating. In our general experience working with wrinkles in an infrared oven can be extremely tricky and is best avoided!

As for the actual application, it applies like any other powder. The trick is to settle on a film thickness that achieves the effect you and your customer want, as a thinner film may not wrinkle to the same degree as a thicker film. Be certain to always refer to the Technical Data Sheet for accurate thicknesses and cure times.

Translucents

Translucent powders offer a unique finish in a variety of colors. As the name suggests, translucents cover the substrate, provide color (and they can even have metallic added) to the part, but allow a hint of the substrate to show through. Many customers love that effect of a beautiful hue with the suggestion of natural metal showing through and built-in.

Translucent powders offer a unique finish in a variety of colors. As the name suggests, translucents cover the substrate, provide color (and they can even have metallic added) to the part, but allow a hint of the substrate to show through. Many customers love that effect of a beautiful hue with the suggestion of natural metal showing through and built-in.

It is pretty common to find translucents in either polyester or urethane chemistries. With the latter, note the pitfalls we listed above. Polyester tends to be more forgiving than urethanes in that department, though it is somewhat limited in smoothness and exterior durability. At the line level, polyesters are easier to deal with, and urethanes, while trickier, can offer a better overall flow and appearance.

A big pitfall with translucents is that it is very easy to have uneven pigmentation on the substrate, especially if it is an irregular shape – like a table leg. There can be visible differences with as little as half-millimeter variations in film thickness. Due to their nature, these special effect coatings will also allow the nature of the substrate beneath to show through. This can be the main reason why a translucent is used. If it isn’t, laying down a white or silver basecoat is a step you can take – this is especially useful if the surface is not uniform in coloring.

Why Use Translucents?

As we said above, sometimes designers and customers want the metal beneath to show through, just with a bit of pizzazz on top. Translucents are the best way to achieve such a look. Other times, translucents offer an impressive brightness as compared to other coatings. This special effect also works extremely well on stainless steel, and due to the high percentage of resin in them, they apply pretty well.

How Do I Apply Translucents?

Any marks, scuffs, blemishes, and discolorations on the substrate will show through a translucent coating. If a pretreatment does not remove them, then you will need to lay down a base coat of some kind. IFS bright chrome is often used to cover a less than perfect substrate and lay down a bright, even base, before applying the translucent coating on top. This creates a really bright, beautiful finish.

Beyond that, what getting a great result using translucents comes down to is applying the powder evenly to the surface. Keep the gun steady, watch your gun to surface distance, and time how long you spray each section.

Dormants

Dormants have grown in popularity over the last few years and are bright, almost candy effects but with more depth, brilliance and shine. Dormant special effects are a two-coat system, as a base coat and top coat is applied and baked separately. The base coat, which typically has metallic pigment in it, has a color that will transfer up into the clear top coat upon curing of the second coat. So it’s the top coat, which is actually clear, that really draws the dormant color out and brings the dormant to life. For example, a red will appear as a dull pink before the top coat is added This also means that you need to make sure you use the base coat and top coat designed to work together, otherwise you risk all sorts of problems.

The top coat is a clear powder, which is great news as that means they are resin rich. So when purchasing formant effects make sure you get the base color coat and a clear that is designed to give the dormant effect and work together. As dormants are a two coat system, check out our blog and top tips for applying two coats!

Why Do We Use Dormants?

While needing a top coat means adding time onto a job, dormants are wonderfully bright colors with more depth and sheen to them. Bicycles are one product that has really utilized dormants in recent years – so imagine that deep, intense color on the frame and you have a good idea of what they look like. Dormant systems also transfer color much more consistently than translucents and are more forgiving than the latter when it comes to film builds and uniform pigmentation. The use of a top coat also offers additional weathering protection and corrosion resistance.

How Do I Apply Dormants?

It is pretty simple. You lay down a base coat – your color – and bake. Then you lay down your top coat, and bake. Easy as that.

Watch out for back ionization when applying the clear! Use a recoat setting and follow our tips for reducing back ionization or KV rejection. Another thing to consider is where the substrate will be located. Indoors, or outside? Check with your powder manufacturer what chemistry their dormant powder is available in and whether it is suitable for the end use.

River Vein

A river vein is a particularly unique effect. Both IFS and Polychem have a huge range of river veins available in a wide range of colors. It’s definitely worth checking out what they look like with one of our color cards – they’re really popular but are best seen in the flesh (as it were) – pictures don’t do them justice.

A river vein is a particularly unique effect. Both IFS and Polychem have a huge range of river veins available in a wide range of colors. It’s definitely worth checking out what they look like with one of our color cards – they’re really popular but are best seen in the flesh (as it were) – pictures don’t do them justice.

Usually, river veins come in polyester technology, though they are available in other chemistries such as hybrids and epoxies too. It is easy for appearance issues to crop up with this special effect. Paying close attention to your film thickness and what the TDS calls for will help here. If it requires three to four mills, you really want to be in that range.

Film build really is absolutely key when it comes to applying river veins. Due to the nature of the effect, spray it too thin, then in the “valleys” of the special effect, you can actually see the substrate showing though – not the look we are going for. Consistency is key.

Consistency and film build also affect how the veins themselves appear, especially if you are doing a batch of, for example, tables for a customer. You want uniformity across the line. If your film is thicker on some tables and thinner on the others, the deviations will be visible. Not a good outcome.

When it comes to deciding between hybrid, polyester, or epoxy chemistry for river vein powders, knowing where the coated end product will be situated will help. Hybrids offer more resistance than polyesters, however, hybrids will chalk if placed outside. Cross reference what your customer needs with what powders you use.

Why Do We Use River Veins?

Aesthetically, they offer an interesting look. Plus, if a surface looks....shall we say, like an ugly duckling, river veins can bring out the transformation into a beautiful swan? Okay, that was a metaphor that reached a little far, but you get the picture.

How Do I Apply River Veins?

Generally, river veins are applied like any other powder – stick to the guidelines and mind the information on the TDS. Pretreat, apply, bake, and top coat if necessary. Ta-da! And remember, watch your consistency and film build at every step!

If you are reclaiming these products, you want to be sure to keep a high percentage of virgin in the reclaim, otherwise you might start to see some shifts.

Multi-Components

How to describe multi-components? Seeing is believing, but many of our customers are simply amazed that such a beautiful effect can be created in a single coat. Gets OEM free panels from Polychem to check out some awesome multi-component looks. Trust us – pictures simply don’t do them justice. Given the versatility of multi-components, it is easier to say that what chemistry you use depends on where the coated end product will be used. For example, if the customer needs good weathering, then a super durable could be a great option. Now, due to the nature of this particular special effect, extra attention must be paid during application. We have said consistency is important a lot in this guide...and we will say it again! Be consistent with your gun-to-part distance! It really does make a huge difference.

Again, if you are reclaiming this powder, you want to be sure that your virgin to reclaim is very consistent and higher on the percentage of virgin going back into the reclaim. Good fluidization is also important for multi-components.

When laying out the outlines for a job involving multi-components, it is important to set a standard for what the finish will look like. Setting this standard, working out how much leeway you have for the appearance of the final product, will save you some pain – especially if you have a sample panel to show the customer.

Why Do We Use Multi-Components?

They offer a really unique look to a part and can also offer great hiding. There isn’t much more to say than that!

How Do I Apply Multi-Components?

Generally speaking, multi-components, apply like any other powder. However good fluidization is really important. Box feed

systems can struggle with these effects – bear that in mind. Good control of your application equipment is also important. Ensuring you use the same KV and micro amp settings every time and the same gun to part distance is important – consistency is key. You will get two very different results if you hold the gun at a different distance to the part each time, Also, if you are reclaiming, be sure your virgin to reclaim mix is very consistent with a higher percentage of virgin going back into the reclaim.

Fine Textures

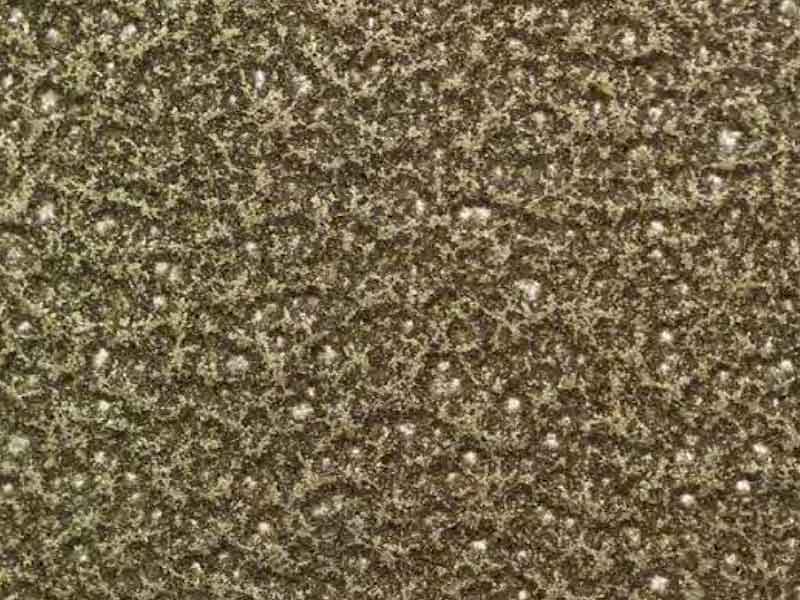

Job shops, designers, and suppliers will all have their own variations on what they define as a fine texture. At IFS Coatings we consider fine sand and grit to be a fine texture. Sometimes, a fine texture can be so faint that it is hardly visible. At the base level, fine textures are powders with a texture added in alongside the pigmentation. They’re great for hiding substrate defects and also for achieving a more matte look.

Because of this added texture, one thing to be noted is that the more texture you build up in a film, the lower the gloss effect will become. Another factor to keep in mind is that textures, fine or heavy, can cause a fair bit of wear and tear on your equipment. Reclaiming equipment, fluidizing hoppers, hoses, and the internals of spray guns can all be affected. If you are spraying textures frequently, dedicated equipment might be in order – you do not want a texture powder to contaminate another.

Why Do We Use Fine Textures?

Let’s be honest, okay? Sometimes fine textures are used to cover up cruddy welds and surfaces. It can be for a specific look a designer wants, of course, and heavy textures are often used to create anti-skid surfaces – like RV steps. But, textures are often used as a concealer.

How Do I Apply Fine Textures?

Fine textures are somewhat more forgiving than the other special effects we have covered. In general, so long as you are consistent in film thickness, it applies and cures like any other coating. Still, a good rule of thumb is not to go too heavy or too light. Keep it just right.

One final time...Consistency. Is. Key! Texture builds up quicker than you think, and it will be rather obvious if the film is not

uniform in thickness. Mind your gun distance. Clear up exactly what is required of the product with the customer, too, and figure out how much leeway you have concerning the look of the finish. Not every texture will come out looking exactly the same, and it is important that customers know this – we would even suggest a full agreement that the customer signs off on before you start the job. Good practice no matter what the effect.

To Top It All Off

We have covered special effects including wrinkles, translucents, river veins, dormants, multi-components and fine textures. They are a versatile category of coatings that offer unique and interesting aesthetics and come with their own pros and cons. While some are trickier to apply than others, learning the ins and outs of them in a step in the right direction to mastering their techniques. The more you learn, the more you can offer your customers.

For further questions or inquiries drop us a line at coatingsinfo@ifscoatings.com

Fiona Levin-Smith is Vice president of Marketing and Specification for IFS Coatings. For further questions or inquiries, visit www.ifscoatings.com