Have you considered how an in-line paint stripper can cut costs, improve quality, and boost capacity?

Larry EnsleyIt is generally accepted that paint and powder coating processes suffer from the overspray that builds upon hooks, racks, and hangers. Consequences include a drop in electrical conductivity, which reduces coating adhesion and results in a poor visual appearance.

Larry EnsleyIt is generally accepted that paint and powder coating processes suffer from the overspray that builds upon hooks, racks, and hangers. Consequences include a drop in electrical conductivity, which reduces coating adhesion and results in a poor visual appearance.

Here are some realized benefits associated with in-line paint stripping:

- Labor cost reduced from 3 to 1 full-time person.

- 67% reduction in rack repair costs.

- 30% reduction in real-time accidents.

- Strip time reduced from 4 hours to 15 minutes.

- Improved ergonomics due to less handling.

The solution is to remove the build-up as often as possible, but that’s something many coaters find hard and expensive. Chipping, burning, and blasting the excess build-up of paint and powder are slow, labor-intensive processes that end up damaging the hooks and racks. Furthermore, swapping out hangers and racks so they can be cleaned in an off-line process creates downtime, which is another expense that most in the industry would like to reduce or eliminate.

What is the impact of applying the seven wastes of lean manufacturing to an in-line paint stripping process?

- Transportation: Eliminates need to move racks from paint process to cleaning area

- Inventory: Eliminates need for excess rack

- Motion: Eliminates need to replace dirty racks with clean racks

- Waiting: Eliminates time wasted when waiting on racks during the cleaning process

- Over Production: Reduces need for excess production to compensate for paint defects

- Over Processing: Reduces the amount of manpower needed to run the process

- Defects: Eliminates defects caused by excess paint on hooks and racks

Fortunately, there is a better way. This white paper explains how coating process operators can save money and improve quality by incorporating an in-line rack and hook stripping process.

Points addressed are:

- The “How” of In-line Paint Stripping

- Chemical Considerations

- Stripper Reuse/Recycling

- System Maintenance

- Typical Benefits

- How to Learn More

The “How” of In-line Paint Stripping

Parts to be powder-coated are hung on metal hooks or racks. This provides an electrical path that creates an electrostatic field. Charged powder particles are drawn onto the parts and onto the hooks, hangers, and racks. As this coating builds up over multiple cycles, it reduces the electrostatic effect, coating adhesion suffers, and so too does the appearance.

Parts to be powder-coated are hung on metal hooks or racks. This provides an electrical path that creates an electrostatic field. Charged powder particles are drawn onto the parts and onto the hooks, hangers, and racks. As this coating builds up over multiple cycles, it reduces the electrostatic effect, coating adhesion suffers, and so too does the appearance.

Coating equipment operators have tried a variety of ways to remove this build-up. These include:

- Physically chipping it away by hand with hammers and pliers.

- Sandblasting

- Burn-off ovens

- High-temperature molten salt baths or fluidized sand beds

- Off-line chemical stripping processes

All the methods above incur downtime and add labor costs during the cleaning methods. They are labor-intensive, risk damaging the hangers and racks, and most important, require coaters to maintain surplus inventory of the racks and hangers in order to continue the paint and powder-coating processes. The surplus inventory of racks and hangers also adds cost and consumes valuable storage space while they are not in use.

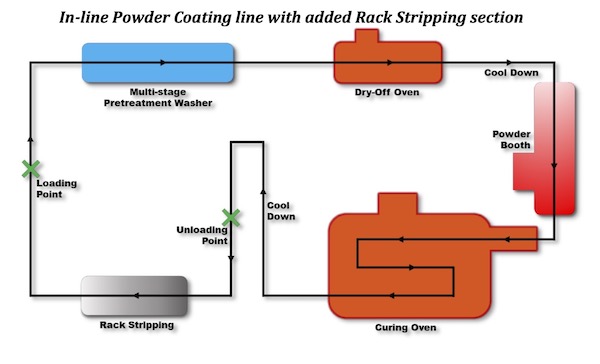

An alternative to the methods above is an in-line stripping process, which adds an immersion tank to the coating process after the part unload point. Empty hangers travel through the stripping solution to remove a single coat of paint or powder build-up. The immersion tank contains heaters, circulation pumps, and eductor nozzles to reduce the time required to strip the racks. The racks are rinsed and cycled back to the rack loading station, where the process is repeated.

In-line Powder Coating line with added Rack Stripping section:

Chemical Stripper Considerations

Another important consideration when designing the in-line paint stripping process is to ensure that the proper paint stripping solution is installed in the strip tank. The paint stripping solution must be compatible with the material of construction of the racks and hooks, and the stripping solution must be effective on the type of paint or powder coat being removed.

Stripper Reuse/Recycling

What happens to the coating that's been removed? The in-line paint stripping system includes in- tank agitators and a circulation system with pumps and filters. Agitation keeps the coating residue in the solution until it’s drawn into the pumps. The pumps push it through filter bags that separate out much of the stripped coating.

The clean stripper solution is then returned to the tank, where it continues to do its job. This filtration process means there’s minimal consumption of stripper and less tank maintenance, which keeps operating costs low.

System Maintenance

An in-line paint stripping system is close to being maintenance-free. However, despite agitation and filtration, some residue will accumulate at the bottom of the dip tank. This needs to be decanted periodically and disposed of per local regulations. The resulting downtime is just a few hours per year, and it is minimal when compared to the maintenance required on other paint stripping processes. Likewise, filter bags will need periodic replacement, but again this maintenance is minimal.

Typical Benefits

Paint and powder coat operators who install in-line stripping realize benefits in four areas:

- Coating quality

- Ergonomics and safety

- Downtime/availability

- Costs

Coating Quality

It's hard to measure how well a coating adheres to the substrate. Sometimes the first indication of a coating problem is when it starts to flake off. While poor adhesion has many causes, inadequate electrical conductivity is a common reason. By stripping the excess coating from racks and hangers-on each cycle, not only is good conductivity assured, but it's also consistent every time. Appearance is another issue affected by poor electrical conductivity, which can lead to an uneven coating and defects.

Ergonomics and Safety

Removing excess coating by hand is a serious health and safety issue. Furthermore, a manual paint removal process is time-consuming and inefficient. It is also inefficient to physically inspect each contact point on a rack or hanger, and there is wasted motion when racks and hooks are removed from a conveyor and replaced with a clean one. An in-line paint stripping process eliminates these costly inefficiencies.

Downtime/Availability

If the coating line isn't running, it's not making any money, and with many coaters operating on razor-thin margins, any loss of capacity eats into profitability. If spare racks and hangers are available, swapping them out costs output. And if spares aren't available, shutting the line down for cleaning will deliver a major financial hit.

Costs

All the paint stripping options, other than an in-line process, add unnecessary costs and labor. Plus, in-line stripping all but eliminates the damage and wear caused by other removal methods. Operations that have gone to in-line stripping report labor savings of up to 67%. In addition, to seeing consistent improvements in quality yields. Rack and hanger replacement is another cost avoided by going to in-line stripping. On a high-volume line, this can easily add up to thousands of dollars saved per year. Yet more savings are realized in terms of consumables used for off-line stripping.

How to Learn More

Many coating plant operators look at stripping as a necessary evil. Some don't even calculate the costs. Those that do realize in-line stripping is an opportunity to make substantial savings while at the same time increasing capacity and improving product quality. To learn more, schedule an initial discussion with a specialist who can help.

Larry Ensley is the technical service manager at Hubbard-Hall. please call 1-800- 648-3412 or visit www.hubbardhall.com